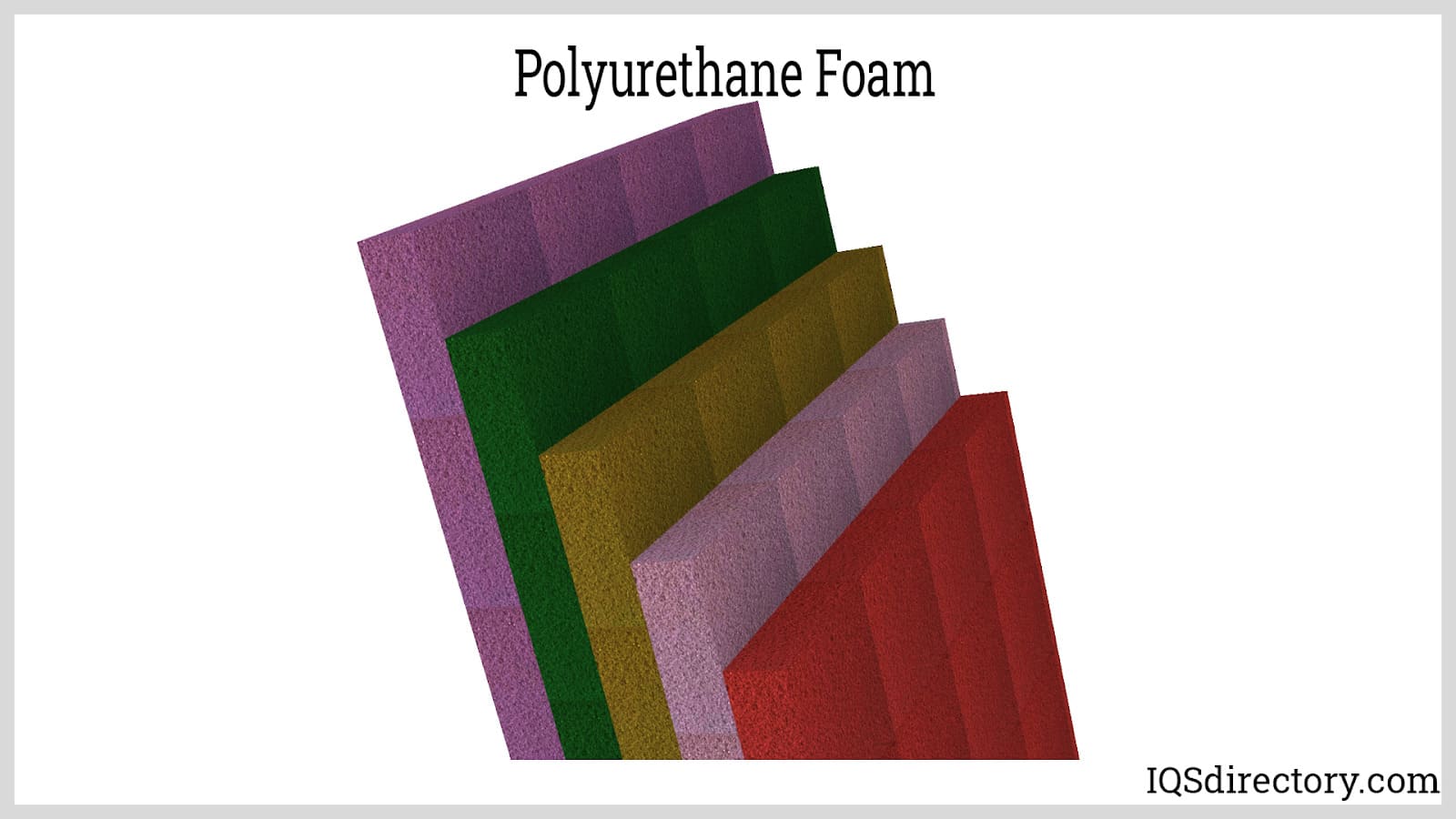

Polyurethane foam is a linear polymer made of organic units connected by carbamate linkages. The chemical formula is C27H36N2O10. There are also thermoplastic polyurethanes. However, most polyurethanes do not melt when heated, making them thermosetting polymers. Di- or tri-isocyanate and one polyol are typically and regularly used to generate these polymers. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Polyurethane Foam Companies

Additional ingredients are added to enable the modification of the polymer's processing or qualities. Polyurethane foams are categorized as alternating copolymers because they are made up of two types of monomers that polymerize one at a time. On average, each molecule of the polyols and isocyanates used to create polyurethanes contains two or more functional groups.

Polyurethane is also another varnish of the synthetic resin variety, and it is made with various methods for different needs. The carbonyl carbon in urethane is attached to both a -OR group and a -NR2 group. It is a functional group that contains carbonyls. A polyester or polyether with a hydroxyl terminal reacts with an isocyanate to produce polyurethane.

Manufacturing Process of Polyurethane Foam

The typical method for making polyurethane involves combining two different liquid streams. More than two liquid streams may occasionally mix. Surfactants and catalysts are typically present in the first stream, also called the polyol stream. Blowing agents are also reported to be present in this stream. Other significant additives are in the other streams, influencing the final product's polyurethane. The resin mix additive stream uses cross-linking, chain-extending, pigment, filler, and flame-retardant materials.

Applications of Polyurethane Foam

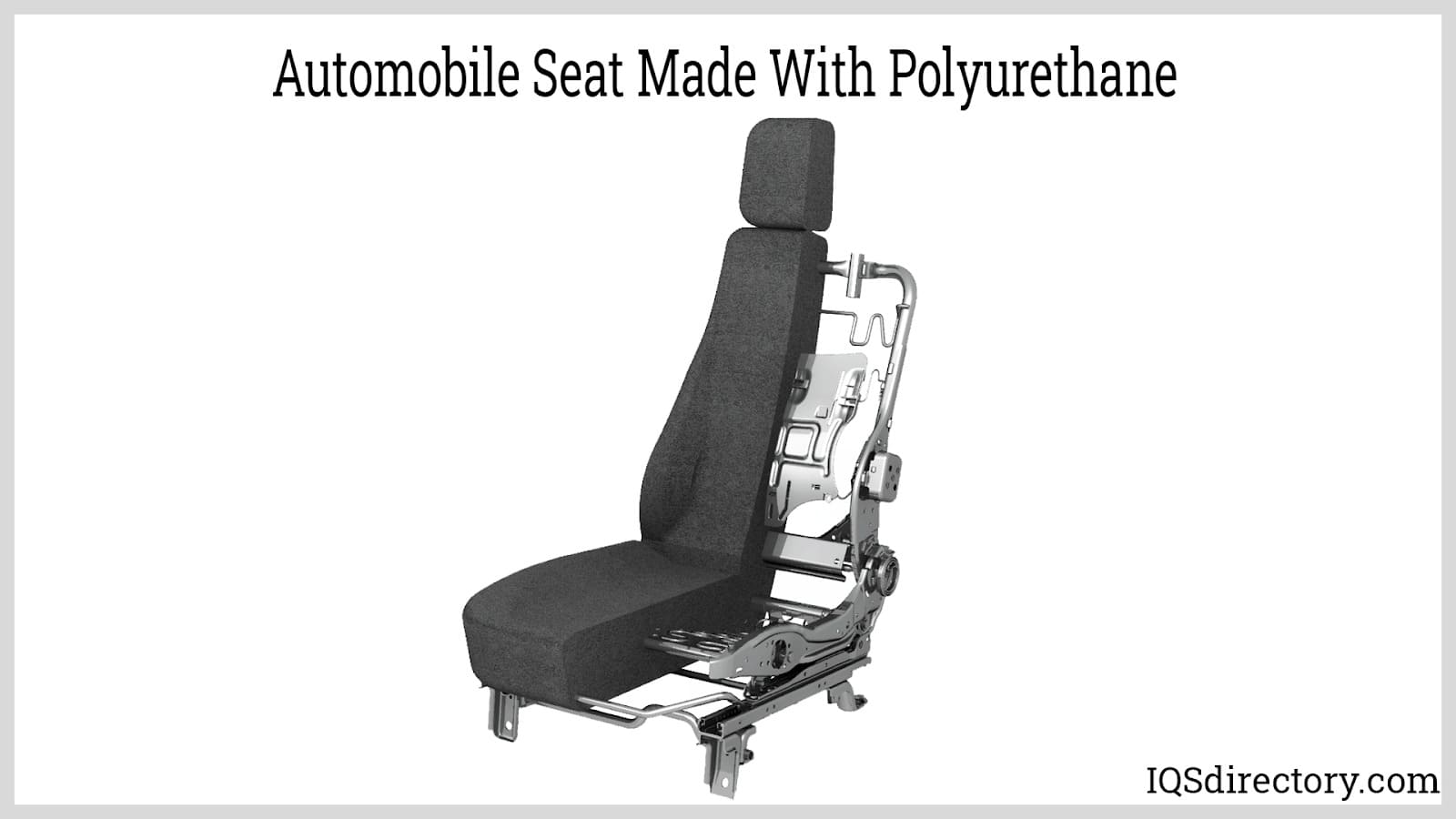

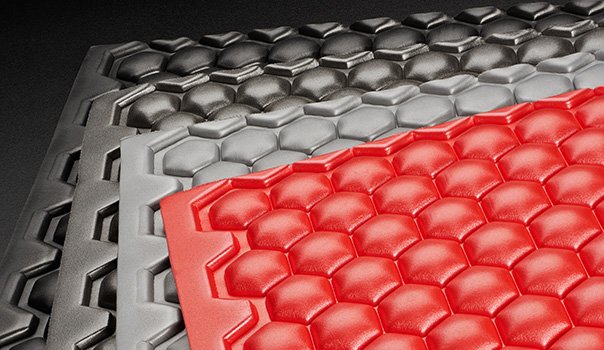

Three-quarters of all global usage of polyurethane is in the form of polyurethane foam, which has a variety of purposes. There are markets with both flexible and stiff foam types. The flexible foams are positioned behind the upholstery fabrics in residential and commercial furniture, while the rigid ones are positioned behind other materials. Diisocyanates, polyols, supplementary blowing agents, catalysts, and other additives are combined to generate flexible foams, which are then allowed to expand naturally. In addition to furniture, they create mattress padding, carpet cushions, and automobile seat cushions.

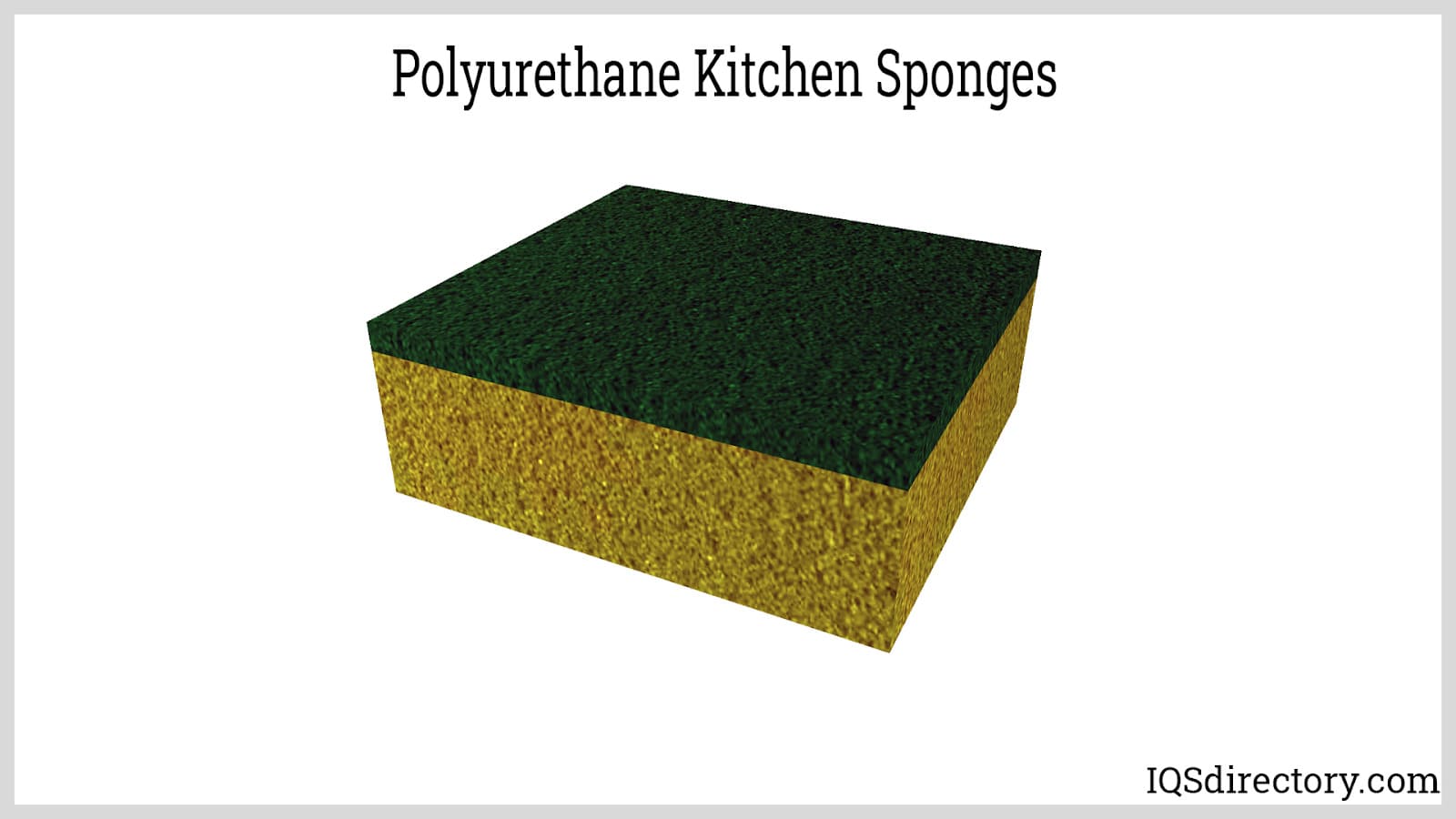

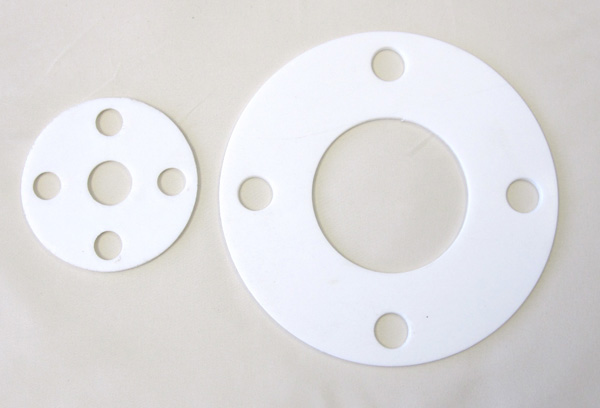

On the other hand, rigid foams are positioned between metals, freezers, refrigerators, and plastic sheets. Polyurethanes are being used more frequently in the clothing industry as well. It is utilized, for instance, to line brasserie cups. Manufacturing different kitchen and bathroom sponges is another application for polyurethane foam. Other uses for polyurethane foam include: highly flexible and robust foam seating, rigid foam for insulating panels, gaskets and seals made of microcellular foam, elastomeric wheels and lasting tires, rubber bushings for automobile suspension, and carpet padding.

For one specific and common example, polyurethane is used to make car seats. In this process, the seat maker has a mold for each kind of seat. The seat cushion is quickly cast using the mold, a closable "clamshell"-style construction. After the seat cushion is removed from the mold, it is upholstered.

Advantages of Polyurethane Foam

Medium-To-Firm Density: Although polyurethane is sometimes thought of as light and flimsy, the foam is medium to robust. This indicates that it won't sag under weight like a memory foam mattress, but it also suggests that it won't be as soft as a latex mattress.

When used for mattresses, polyurethane foam's firmness can be modified to a certain extent. There are two ways to accomplish this. One is to increase or decrease foam. The alternative is to select a mattress with various firmness levels in various bed regions.

Low-Cost Option: Polyurethane foam is less expensive than memory foam and other types. For instance, both latex and polyurethane are less expensive than memory foam.

Alleviates Back Pain: Foam made of polyurethane effectively reduces back pain. It offers strong support and can enhance posture, which assists lessen pressure points that cause lower back pain. Additionally, polyurethane foam lessens the pressure on the spine and helps ease stiffness, edema, and irritation in this region.

Simple to Clean and Maintain: Polyurethane foam is simple to clean and maintain. A polyurethane foam mattress cover can be washed and frequently vacuumed or cleaned with a moist cloth.

Resistant, Long-Lasting, and Durable: Polyurethane foam has all three qualities. Also, mattresses of these material are more space-efficient than the majority of other mattresses; they can fit in smaller places because they are more compact than a memory foam mattress.

Choosing the Right Polyurethane Foam Supplier

To ensure the most constructive outcome when purchasing polyurethane foam from a polyurethane foam supplier, it is important to compare several companies using our directory of polyurethane foam suppliers. Each polyurethane foam supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each polyurethane foam business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polyurethane foam companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services