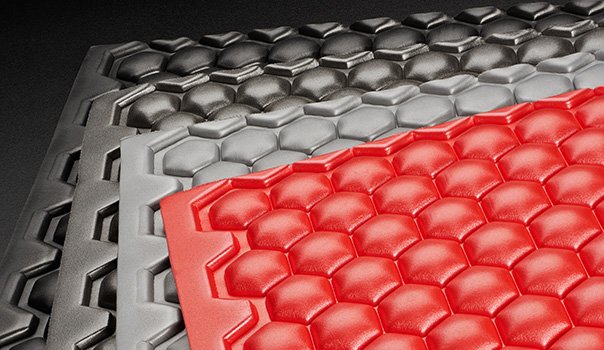

Closed-cell foam is a robust and flexible plastic rubber material with internal pores or cells. Closely spaced but unconnected, these closed-cell foam’s internal cells are located next to one another; the structure is comparable to a net packed with balloons.. The cells of this foam resemble tiny gas-filled bubbles, setting it apart from other foams. Closed-cell foam comes in various forms and sizes, is extremely resilient, and is waterproof. In addition, closed-cell foam comes in a huge range of densities and materials. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Closed Cell Foam Companies

Manufacturing Process Of Closed-Cell Foam

Closed cell foam is made by introducing a gas, often nitrogen, under high pressure to rubber and plastic compounds. High pressure pumps the gas into the material's liquid mixture, forming a compact, bubble-wrap-like structure with tightly packed cells.

There are two approaches to the procedure:

- By immediately exposing the substance to the gas

- By incorporating gas-forming agents into the substance

To meet a variety of purposes and requests, closed cell foams are offered in a broad and varied spectrum. Industries like automotive, medicine, sports, and even construction, to mention a few, benefit from closed-cell foams due to the variety of uses for which it is available.

Types Of Closed Cell Foams

Closed cell foams, as previously indicated, are available in different shapes and sizes and frequently go by several names that overlap. In addition, each foam's manufacturing variations and advantages might occasionally be difficult to distinguish since they are so minor. A handful of the possibilities on the market are listed below.

Polyethylene Foam

This closed cell foam, also known as ethafoam, is intended to be strong, durable, impervious to water and other liquids, and stain-resistant.

Additionally, it has good shock absorption, the capacity to suppress sound, and the ability to stay afloat. Due to these qualities, closed-cell foam is perfect for delicate packaging and arts & crafts applications.

Polyethylene Rolls

Although closed-cell foam is still useful for some purposes when used in rolls, the strength and durability of thicker versions make them more effective. Closed-cell foam can also be molded into polyethylene rolls. For piping and plumbing needs, medical and other healthcare products, sporting goods, and the automobile industry, closed cell foam roll is frequently utilized.

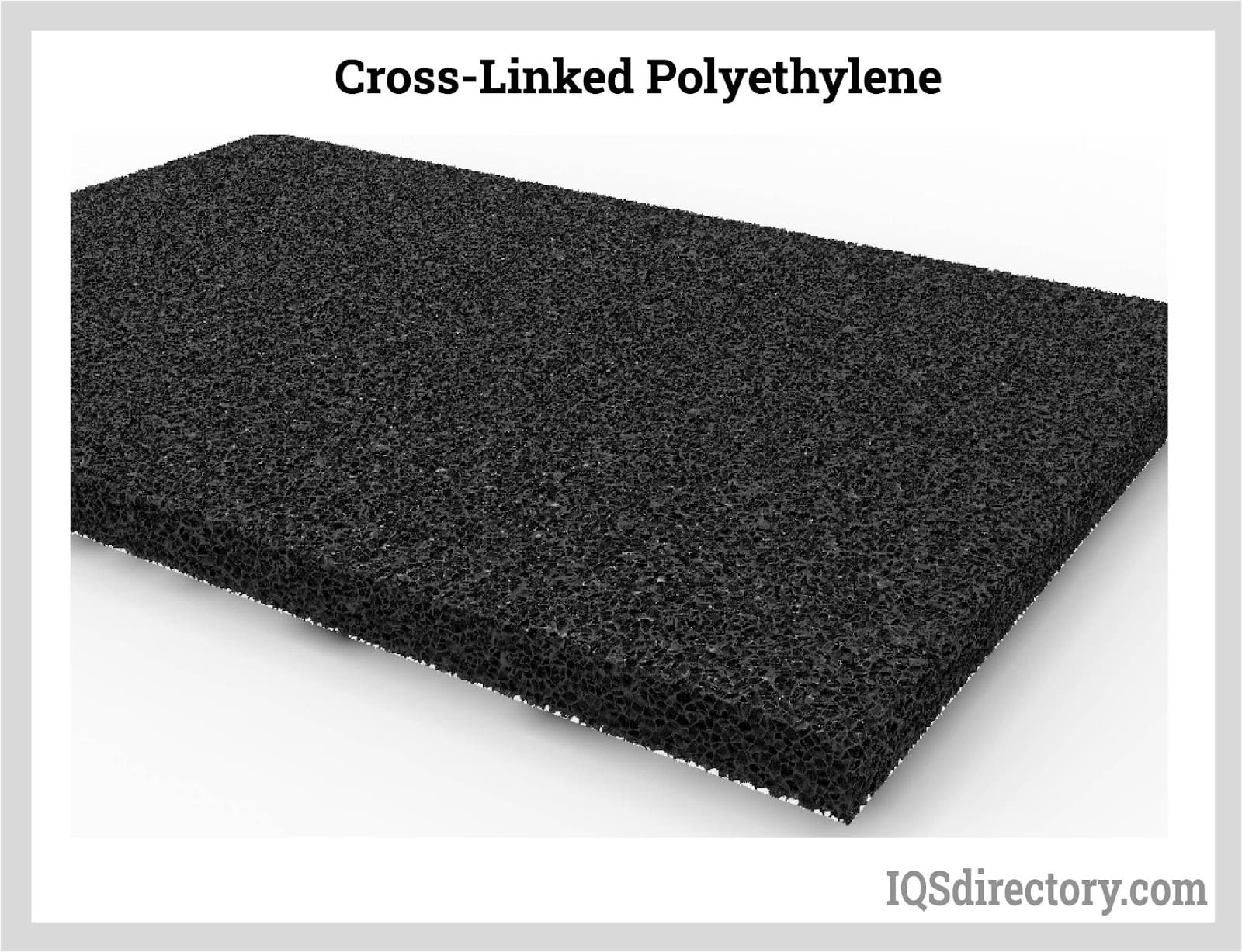

Cross-Linked Polyethylene

Cross-connected foam, or cross-linked polyethylene, is another kind of closed-cell foam that comes in a robust variety and is useful for many applications. In addition to being water, air, and stain-resistant, this form is resistant to mold and mildew. Another benefit of cross-linked polyethylene is that it looks better than conventional foams, which makes it a great choice for packaging needs for branded goods. This type is frequently utilized in building, packing, and floating devices.

Polystyrene foam

Depending on the quantity and use, polystyrene can be purchased as single units or even in multi-packs. It comes in various shapes, including blocks, spheres, and sheets. This form of closed-cell foam also offers the choice of several densities to meet different purposes.

Advantages Of Closed Cell Foam

- Closed-cell foams have a wide range of uses and come with several advantages, some of which are as follows:

- Closed-cell foams are waterproof. This is because this type of foam's cells are so tightly packed together that there is little room for water to sneak in. This reasoning holds for all substances with a highly water-resistant cellular structure closely woven together.

- Foam pores with closed cells can clean themselves, aiding in preventing glazing.

- Since the material is both lightweight and tear-resistant, closed-cell foams are long-lasting and durable.

- Foam with closed cells is stiffer and more durable. Closed-cell foam tends to be more durable than open-cell foam because of its increased rigidity, and it typically keeps its shape for longer.

- Due to their tightly packed cellular structure, closed-cell foams operate as an air barrier, are waterproof, and have outstanding insulating qualities.

Disadvantages Of Closed Cell Foam

- Despite their many advantages, closed-cell foams have a few drawbacks that should be considered before buying or using them in goods.

- It has decreased shock absorption. Due to its compact cell structure, closed-cell foam may have poorer shock absorption capacity than open-cell foam.

- Compared to open-cell foams, closed-cell foams are less "breathable."

- Closed-cell foam won't plug smaller gaps. Due to its rigidity, it performs worse when filling small cavities. It fills gaps more rigidly than fillers do.

- The higher density of the closed-cell foam is another drawback, indicating that the foam is stiff and inflexible compared to the other conventionally available alternatives. It is larger and more likely to shatter.

Choosing the Correct Closed-Cell Foam Supplier

For the most positive outcome when purchasing closed-cell foam from a closed-cell foam supplier, it is important to compare several closed-cell foam companies using our directory of closed-cell foam suppliers. Each closed-cell foam supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each closed-cell foam business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple closed-cell foam businesses with the same form.

Die Cutting

Die Cutting Foam Fab

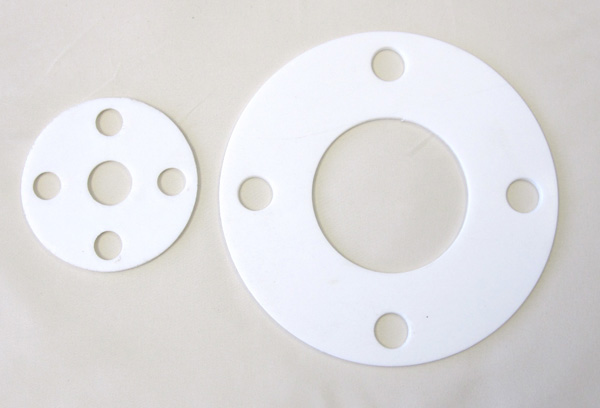

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services