Thermoplastic foam is typically a sponge-like material, created from frothing and then cooling a molten polymer, such as polyurethane or PVC. It is also available in liquid form. While each polymer makes foam with slightly different characteristics, all share the traits of durability, light weight, low thermal conductivity, mold and mildew resistance, bacterial growth resistance, compressibility and low water vapor transmission. Read More...

Flextech utilizes vacuum forming to mold foam and foam composites that only require defined part geometry on one side of the part. The material is heated and pulled over a male tool or into a female tool. A vacuum draws the foam into and around the tool surface to form the geometry of the part. The part is then allowed to cool and removed from the tool. We utilize this process primarily for the...

More Thermoforming Foam Companies

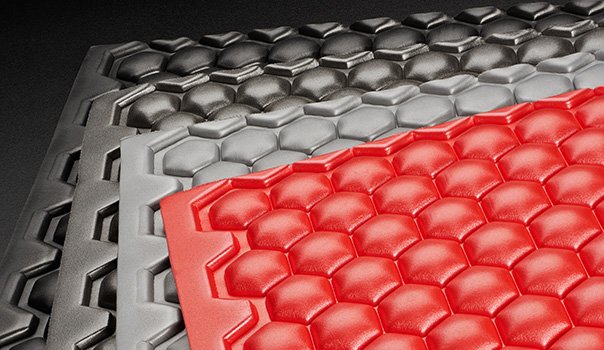

Molded cross-linked polyethylene foam – Flextech, Inc.

Fabricators thermoform two main groups of foam: open cell structured foam (flexible foam) and closed cell structured foam (rigid foam). Open cell foam has pores, or cells, that are joined together, making the foam softer, more flexible, more compressible and easier to break apart. Closed cell foam, on the other hand, contains cells that are closed off from one another and do not compress. As a result, this foam is more firm, compact and pressure resistant.

By thermoforming foam, fabricators can create a wide variety of useful products in a diverse set of industries, including but not limited to: aerospace, packaging and shipping, food service, healthcare, architecture and construction, sound and acoustics, retail and automotive. Some of the many products into which fabricators can thermoform foam are: panel cores, vibration damper pads, shock mounts, portable coolers, shock pads, aircraft crash padding, wall padding for noise reduction/acoustics, aerospace gap filling, packaging, casing, partitions and cushioning.

Thermoforming offers you many options in terms of material composition, foam characteristics, product shape and size and color. In addition, most thermoformed foam is recyclable. Along those same lines, many companies now offer more environmentally friendly foam options. Find out more about thermoforming foam and what this service can do by reaching out to a reliable fabricator, such as those listed on this page.

Die Cutting

Die Cutting Foam Fab

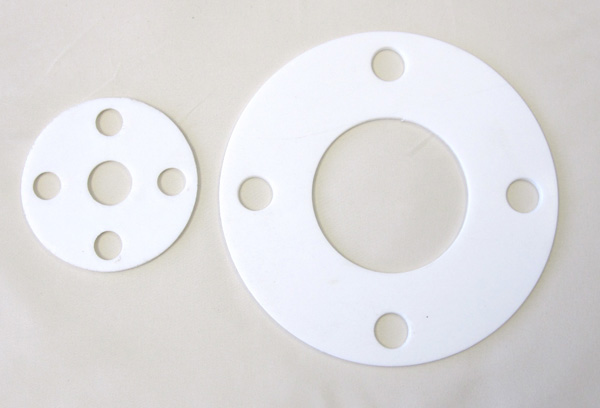

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services