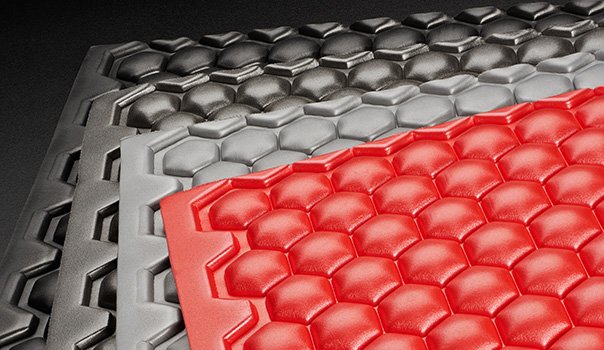

Based upon the application, the foam applicator can be customized into various shapes such as rectangular wedges, round wedges, squares, or other configurations that match the customer’s specifications. The most basic applicators are simply foam pieces which can be used to spread or distribute a separate fluid or material. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Applicator Companies

More complex applicators can be attached to bases and even bottles to simplify the application process. The attached bottles can be filled with the desired liquid which can be dispersed out of the bottle directly into the foam applicator.

These bottles can also be created in a number of colors for color coordinating and are typically converted from plastic.

From consumer to industrial applications, foam applicators are used in many different ways. They are used in tasks as simple as applying makeup and as crucial as dispensing important medical treatments.

For more unique applications, prototyping is a very important step in creating the best foam applicator.

This process allows customers to find the right balance between customization and cost. For example, an automotive company may require a more durable foam applicator to stand up to dirt, grime, wear and tear, but it is more cost effective to use a cheaper disposable foam applicator.

Foam applicator fabricators can help you determine the most essential features and keep your costs down.

Die Cutting

Die Cutting Foam Fab

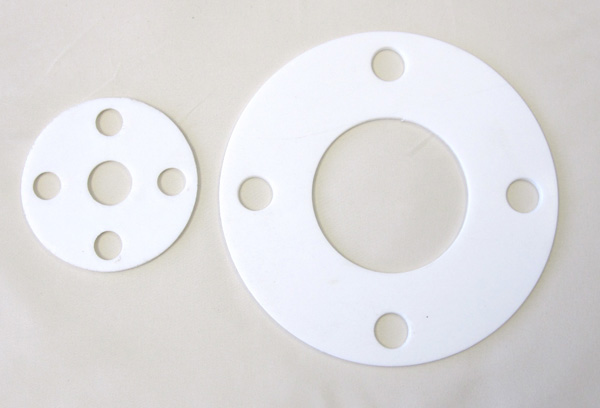

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services