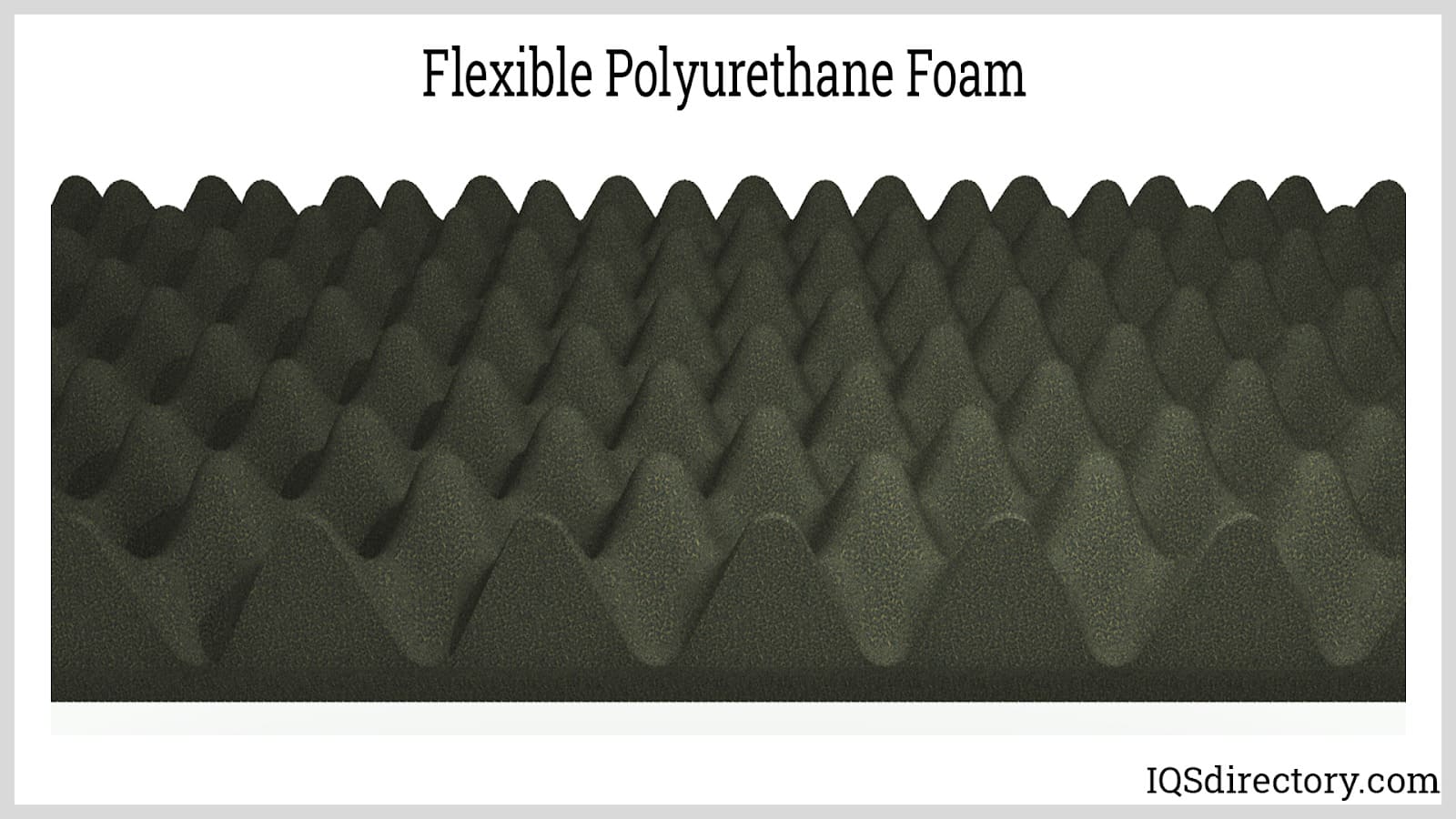

Flexible polyurethane foam (FPF) is a polymer made from a chemical process that combines polyols and isocyanates. FPF is distinguished by a cellular structure that allows for some compression and resilience, resulting in a cushioning effect. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Flexible Foam Companies

What is Flexible Foam?

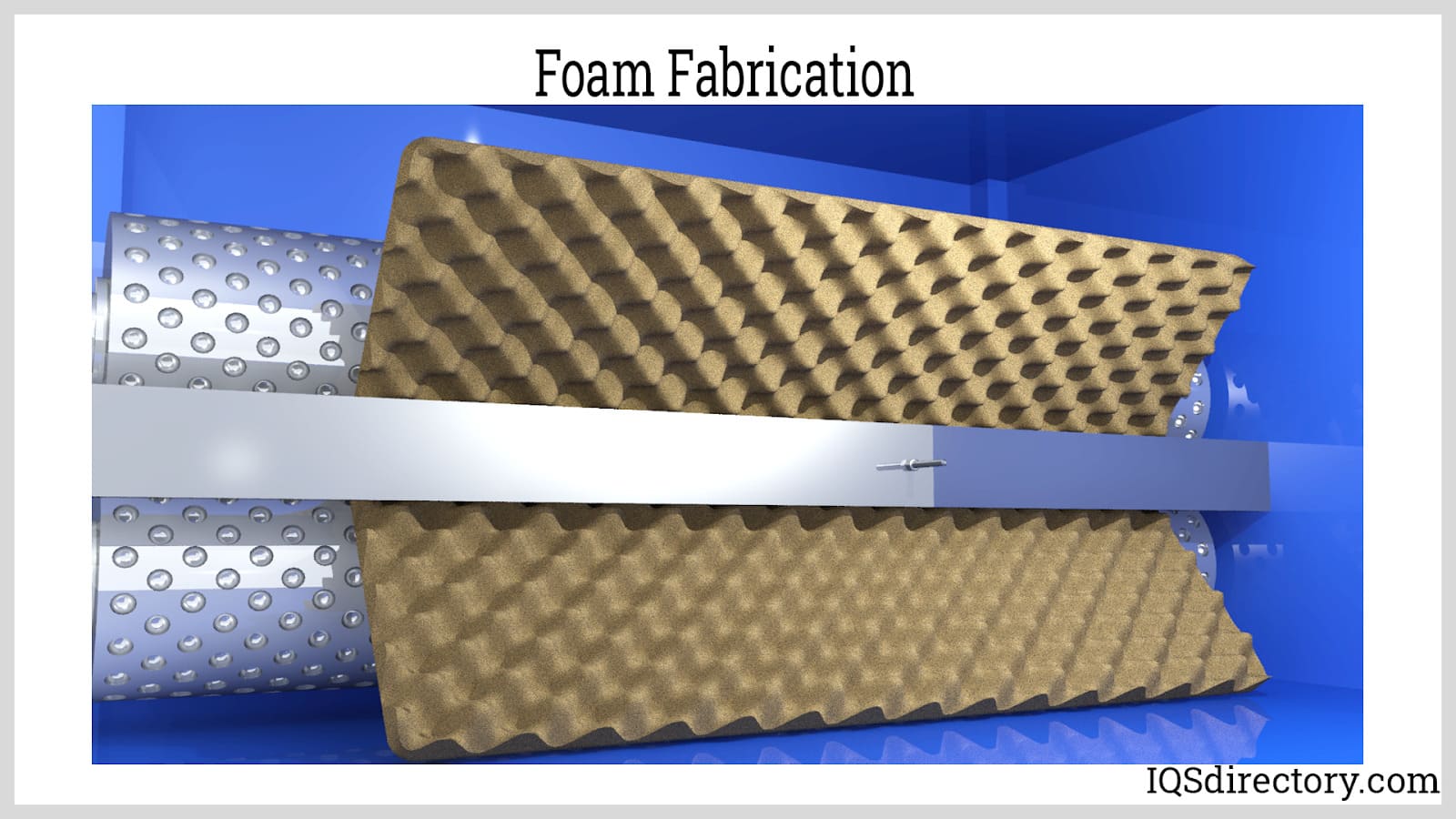

Foam is often made in huge slabstock buns that are allowed to cure into a solid substance before being sliced and molded into smaller pieces in various shapes and designs. When liquid chemicals are placed onto a conveyor belt, they instantly foam up and rise into a huge bun (usually about four feet high) as they travel down the conveyor.

How Flexible Polyurethane Foam is Made

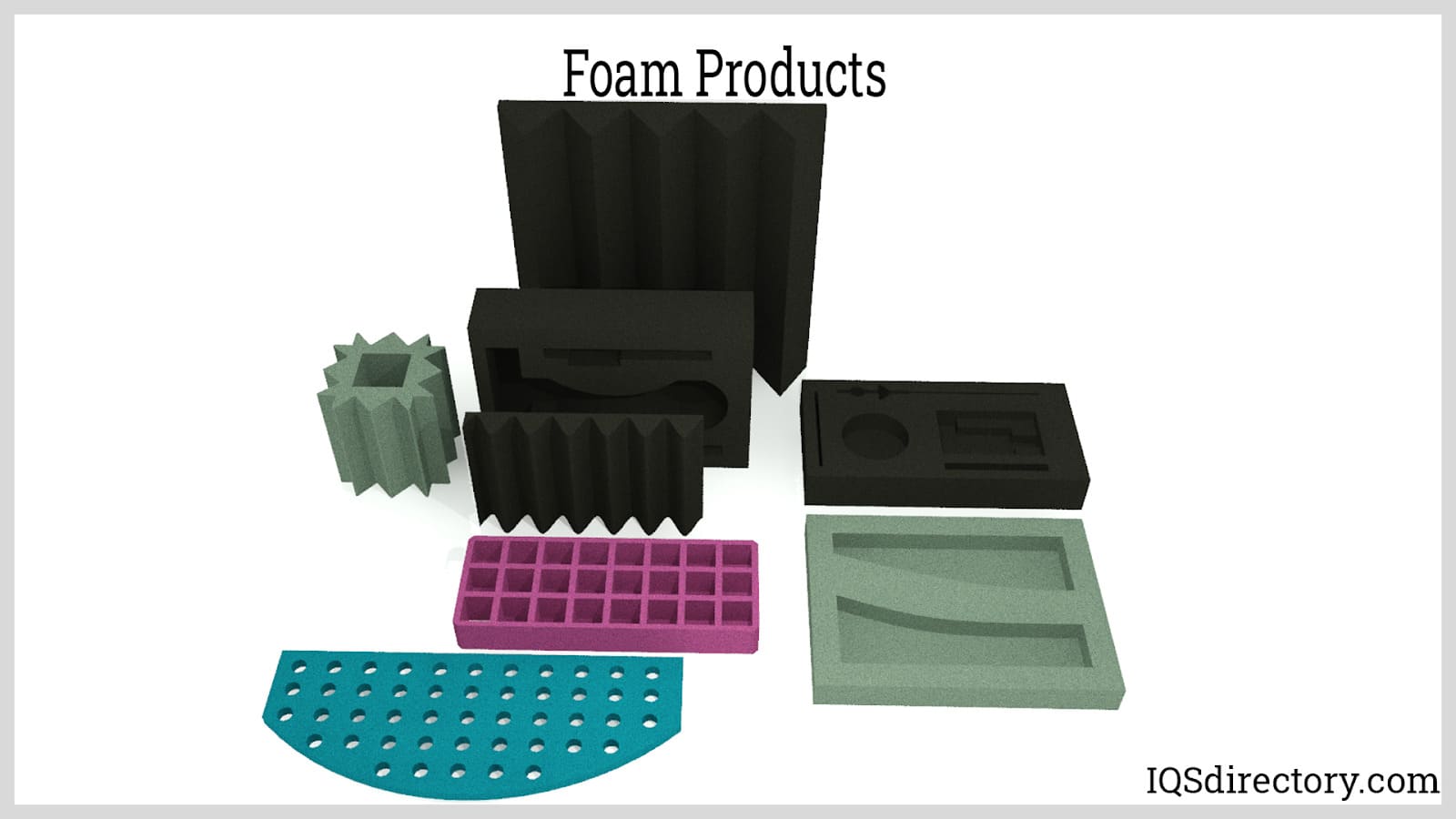

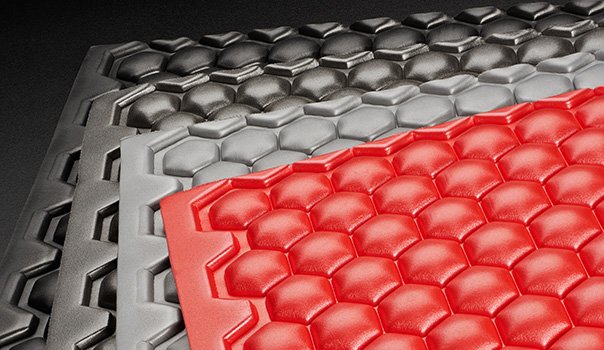

Foaming materials can be poured into aluminum molds, where the cured foam takes on the mold's size and shape. Molding enables the creation of foam goods in shapes that would be impossible to accomplish using slabstock buns. Foam components can be molded along with other parts, such as a metal frame. A car seat's headrest is one example of this. Molding is often reserved for high production runs because of the significant upfront expenses of making molds.

Molded foam is commonly seen in automobile interiors, office furniture, and sporting goods. FPF's fundamental raw materials are frequently supplemented with additives to achieve the desired qualities. These include everything from the comfort and support required for upholstered chairs to the shock absorption required to safeguard packaged products to the long-term abrasion resistance required for carpet cushions.

Amine catalysts and surfactants can change the size of the cells formed during the reaction of polyols with isocyanates, resulting in different foam qualities. Flame retardants for aircraft and automobiles and antimicrobials for outdoor and marine uses are examples of additives. Foam can be fabricated into intricate shapes once it has been created. Vertical bandsaws and horizontal slitters were adopted as fundamental foam fabrication tools.

Foam can be mounted to a vertical wheel with cutting blades because it is flexible, a procedure known as loop slitting. Lasers, hot wires, water jets, wave convolutes, and other technologies are also used by fabricators. Foam can be squeezed while being cut to create effects like "convoluted" foam, sometimes found in mattress toppers.

Properties of Flexible Foam

- The bulk density of polyurethane foam determines its density, not the exact polymer density. The density of a material made with flexible foam shows its cost and load-bearing capacity. The average densities of multiple layers from a sample block are used to calculate this. Perpendicular to the growing axis, the sample block is split into numerous layers.

- Load-bearing capacity measures how much compressive force the foam can withstand without deforming permanently. This determines the firmness or stiffness of the polyurethane foam. Indentation force deflection (IFD) and compression load deflection are two typical methods of load-bearing capability testing (CLD).

Applications of Flexible Polyurethane Foam

Polyurethane can be mixed with nonwoven substrates, netting, cloth, and fiber. Flame bonding, hot film bonding, hot melt adhesion, and powder lamination are bonding processes that use a powder adhesive to heat-attach foam to a substrate.

Other procedures alter foam's structure and performance properties. Reticulation is one of the most dramatic and beneficial changes. To increase porosity and airflow, reticulation involves breaking down many of the foam's cell walls. This can be performed by exposing foam to a caustic solution or a controlled explosion of a gas mixture in a closed reactor. Reticulated foam is frequently employed in air and fluid filtration systems and gasoline tanks as an anti-surge membrane.

The processing of foam scrap into bonded carpet cushions is one of the most commercially important foam reformulations. Various types of scrap foam are shredded and placed in a processing unit with a chemical adhesive. The mixture is compressed and injected with steam to make a huge foam cylinder or block. This material is then "peeled" to the appropriate thicknesses for use as carpet cushions. With a market share of over 80%, bonded foam is the most common type of carpet cushion. Foam qualities can be precisely measured and specified to match the right grade of foam to the particular application.

Choosing the Right Flexible Foam Manufacturer

To ensure the most constructive outcome when purchasing flexible foam from a flexible foam manufacturer, it is important to compare several companies using our directory of flexible foam manufacturers. Each flexible foam manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

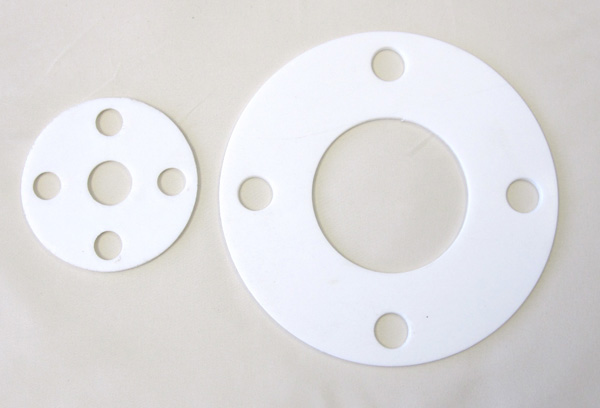

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services