Foam cushions are a common use for both open cell foam and closed cell foam and are found in a range of applications including furniture, foam padding for carpets and upholstery, sports equipment and goods as well as yacht mattresses, bolster cushions, window seats, RV seating and fitness equipment. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Cushion Companies

Foam is a lightweight, versatile and polymer based material that has a spongy feel because of the numerous gas bubbles trapped in the polymer. There are a number of different types of foam that are commonly used, and foam cushions can be made from almost any one. However, the most popular type used is polyurethane foam. It is low compression open celled foam and provides an ideal fabrication material for cushioning and padding use.

In open cell foam, the cells or bubbles of the material are interconnected instead of being separately sealed compartments. Therefore, there is a softer feel to open cell foam than to closed cell foam in which the cells are arranged in a compact configuration. Other types of cushioning foam include: polyether foam which is a low cost type of foam that is also widely used for packaging, cushioning and acoustics.

The main purpose of foam cushioning is to add a level of comfort and shock or energy absorption to both stationary applications such as household furniture as well as those in transit such as automotive seating. In packaging and transportation, cushioning protects products against damage from drops, bumps and mishandling as it is placed around the object and absorbs the shock, preventing damage.

In other uses such as insulation, construction sealing and positioning for a number of applications, foam cushions are an important accessory to those existing structures. As with other foam materials, the variety available within foam cushioning is almost limitless as foam fabricating methods, include foam cutting, can be used to achieve any shape, dimension and size.

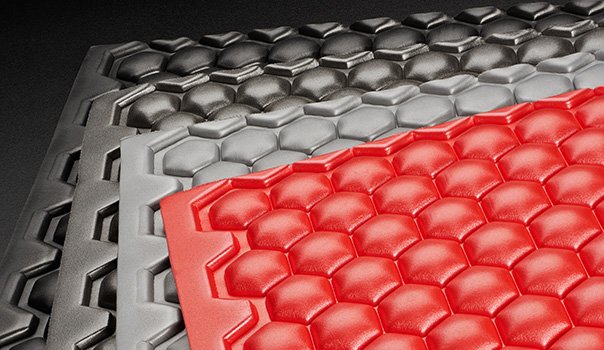

Foam cutting methods include die cutting, hot wire cutting and water jet cutting, although molds can also be used to fabricate very specifically shaped objects. Stock cushion shapes include square, wedge, triangle, cylinder, semi-circle and custom designs. Physical characteristics such as foam density and thickness will be dependent upon the specifics of its intended use in terms of required comfort and frequency of use.

Cushions intended for daily use such as furniture, automotive seat cushions and more require high density foam in order to ensure a long product lifespan before replacement is required.

Die Cutting

Die Cutting Foam Fab

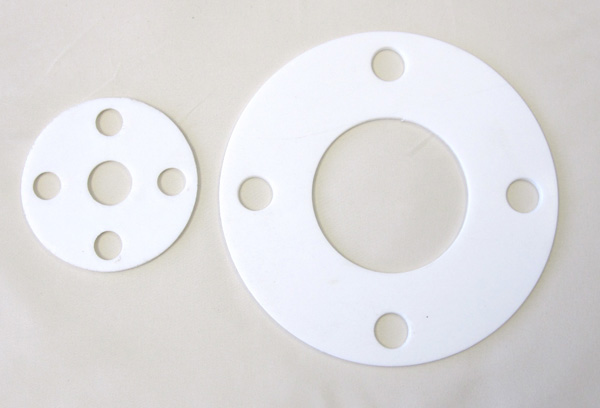

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services