Polyethylene foam is a closed-cell foam that resembles plastic. It is lightweight but resilient, and there are numerous applications for polyethylene foam. In addition, it has a long lifespan, is impervious to moisture and chemicals, and works well to reduce vibrations. These characteristics make this foam ideal for various uses, including packaging, shock absorption, and mild buoyancy. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

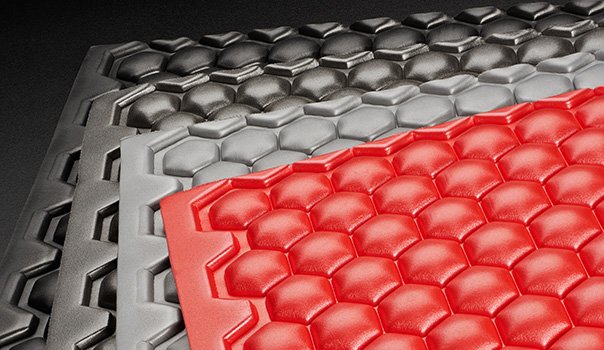

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Polyethylene Foam Companies

Manufacturing Process of Polyethylene Foam

When monomers, such as the one known as ethylene, are strung together and bound, a stable, solid substance that resembles plastic is produced. When a specific property, such as anti-static, is desired in the foam, additives may be added at various stages of the production process.

Polyethene Form Characteristics and Uses

Since polyethylene is a closed-cell foam, it comprises several tiny, hermetically enclosed bubbles. In addition to strength and rigidity not found in open-cell foams, this offers water resistance. It is also antibacterial and resistant to solvents, petroleum compounds, mold, mildew, and bacteria. In addition, polyethylene is a durable material that recovers its original shape after compression while still being flexible enough to offer support and cushion where required. These qualities and its adaptability and customization options make it valuable in many applications.

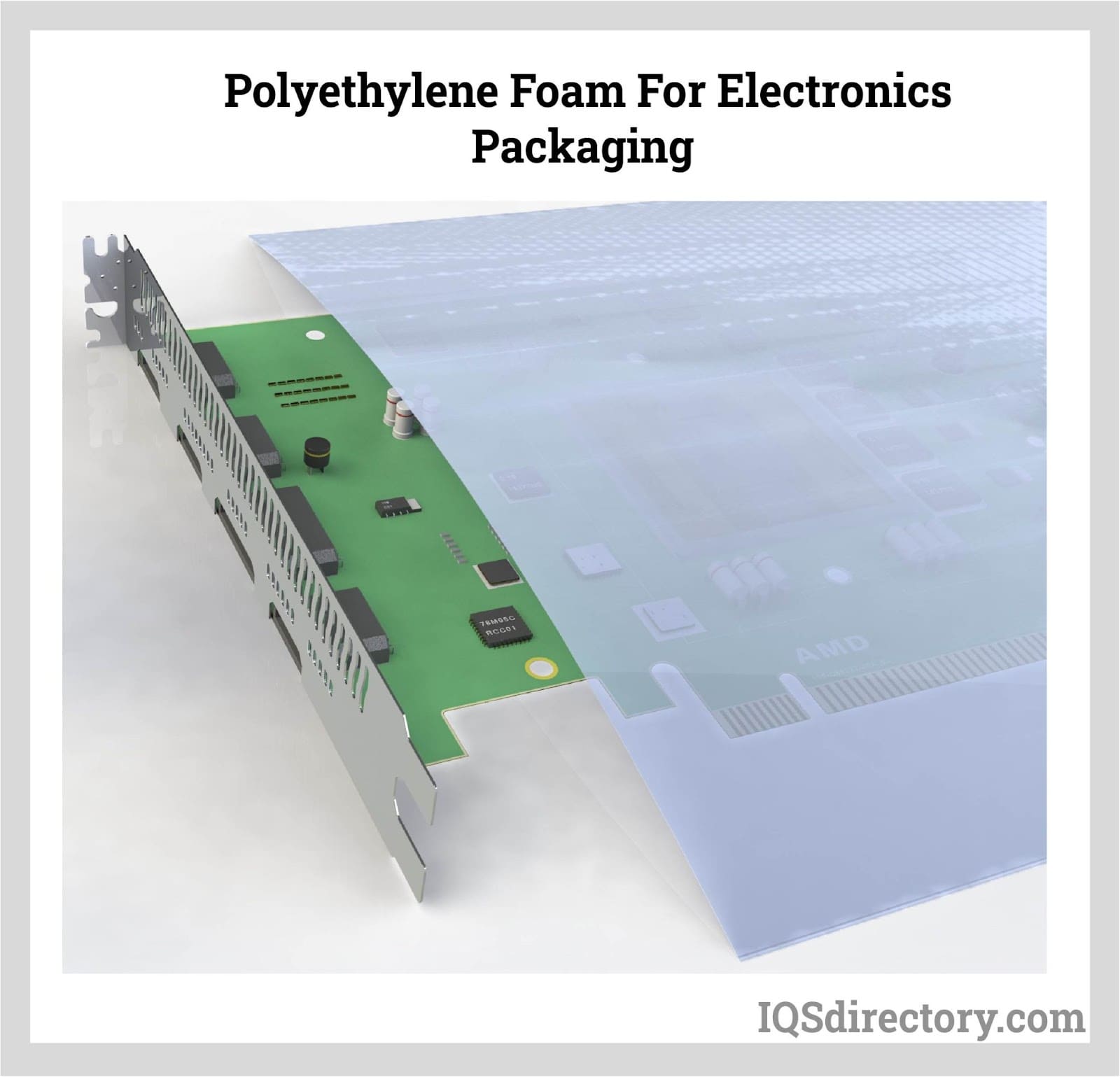

Heating polymer compounds create polyethylene foam, but before it is heated and extruded into its solid state form, it can be given additives to change its properties. Electro-static charges that could accumulate and harm components are dissipated by anti-static qualities, which help with the packing, handling, and transporting of fragile electronics.

In contrast to treatments done after the foam has been formed, the features are uniform throughout the material when additives are part of the composition. It is also offered in various densities, just like other foams. Polyethylene's cell walls get smaller and thicker as its density increases, making the material stronger.

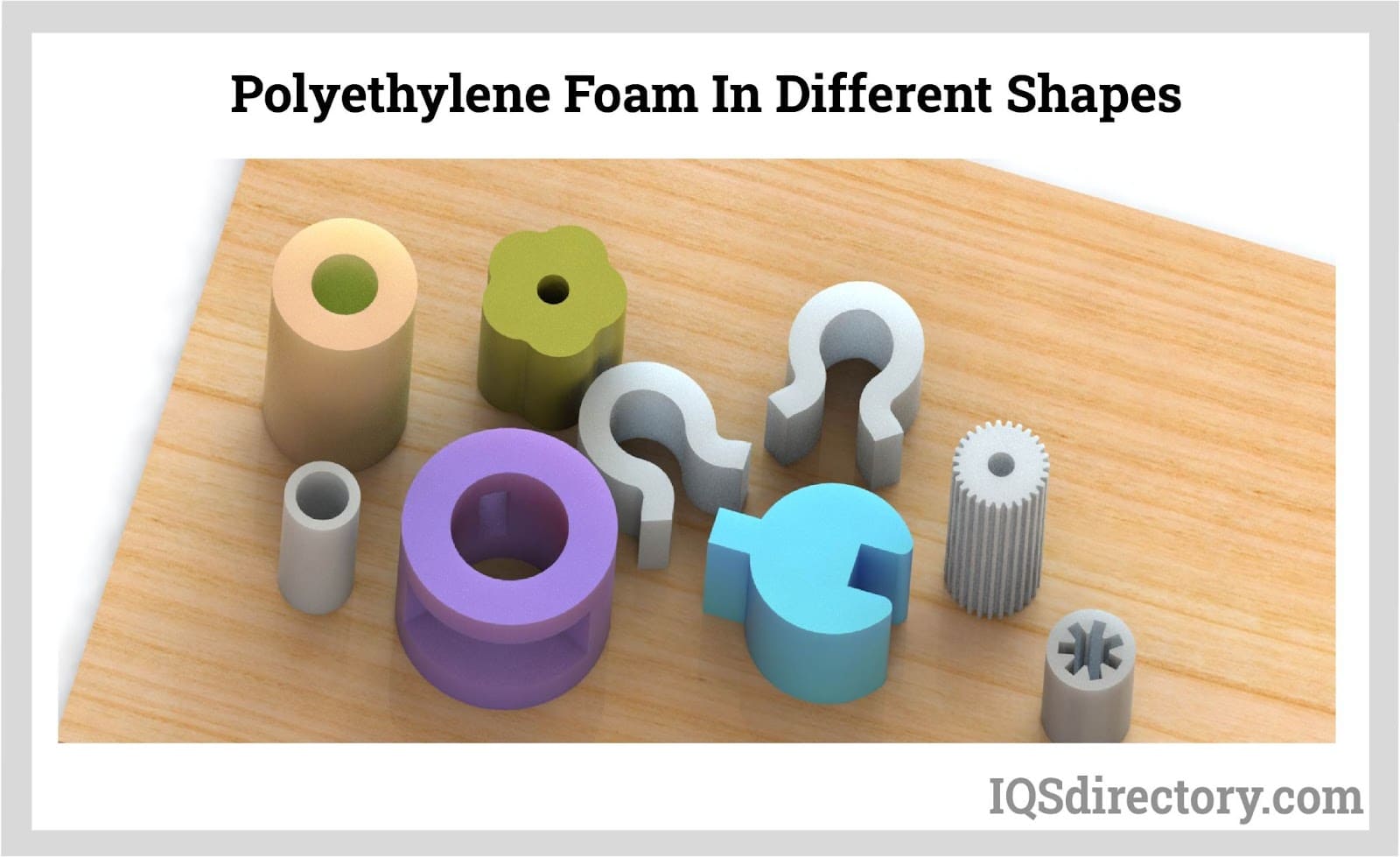

The material can be found in different shapes and sizes in addition to the performance qualities it can have. Polyethylene, most frequently seen in sheet or plank form, is rigid and maintains its shape even when chopped into large segments. While durable and shock-absorbing, polyethylene may be easily cut to create form-fit inserts for securely moving or carrying objects.

As a result, these are most frequently employed as material for insulating or in casing and custom packing. Polyethylene is particularly popular for thermal insulation because it is great at resisting moisture in closed-cell foam insulation. Polyethylene sheeting is also easily combined to make thicker portions that can later be cut for us as furniture inserts, personal flotation device inserts, or specialty packaging. Backer rod polyethylene tube is also produced in various diameters for various uses.

Polyethylene rolls are constructed from incredibly thin sheets of material. Due to its flexibility, it can be made into pouches or bags to protect products while taking up the least amount of space and weight, as well as insulation wrapped around pipelines, seals between foundations, and sill plates in buildings. These cylinders come in various sizes and can be used as bolsters and other personal comfort items. Continuous-length polyethylene tubes are utilized in construction as a backer rod between concrete slabs when produced on a much smaller scale.

The water-resistant foam backer rod creates a cost-effective filler, lowering the amount of expensive sealing substance required while allowing some flex between the two slabs by preventing the formation of a three-way bond. In addition, because of variations in temperature and weather, backing rods can expand and shrink.

Advantages of polyethylene foam

- This foam is one of the alternatives for packaging and transportation applications because it has strong impact absorption and vibration-dampening qualities, which improves the protection of the goods.

- The melting point of polyethylene foam is 80 degrees. However, it can function effectively in high and low temperatures because of its heat-resistant qualities.

- Other benefits of polyethylene foam include its resistance to water, lubricants, solvents, and chemicals. In addition, foam is an excellent insulating material since mildew, mold, and bacteria can't easily ingest it.

- Since polyethylene foam has closed cells, it is typically denser and stronger than open-cell alternatives.

- The essential qualities of this kind of foam are its buoyancy and lightweight properties, which make it the perfect material for flotation devices.

- Another characteristic of polyethylene foam is its resilience under load. It will readily and rapidly resume its former shape when the burden is lifted.

- Being CFC-free, odorless, and non-toxic (unless burned), polyethylene foam is a popular material for mattresses and bedding.

- It is a well-liked option for clothes and apparel due to its thermal insulation and lightweight and water-resistant qualities.

Disadvantages of polyethylene foam

- Polyethylene foam takes a long time to create and process, making it occasionally a more expensive option for applications where alternative foams may perform the same function.

- Polyethylene foam may be prone to tearing or breaking depending on how it is produced.

- Numerous low-quality polyethylene foam production instances have been documented, which can cause issues in the future.

- Although it has been discovered that the raw ingredients used to make polyethylene foam are difficult to recycle, more recent advancements in the recycling sector have made polyethylene foam products more easily recyclable or reusable.

- During combustion, some foams produce hazardous gasses and toxic fumes released into the air. Therefore, other foam or rubber options might be better when combustion is likely.

Choosing the Correct Polyethylene Foam Manufacturer

To ensure you have the most positive outcome when purchasing polyethylene foam from a polyethylene foam manufacturer, it is important to compare several companies using our directory of polyethylene foam manufacturers. Each polyethylene foam manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer or request a quote. Review each polyethylene foam business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polyethylene foam businesses with the same form.

Die Cutting

Die Cutting Foam Fab

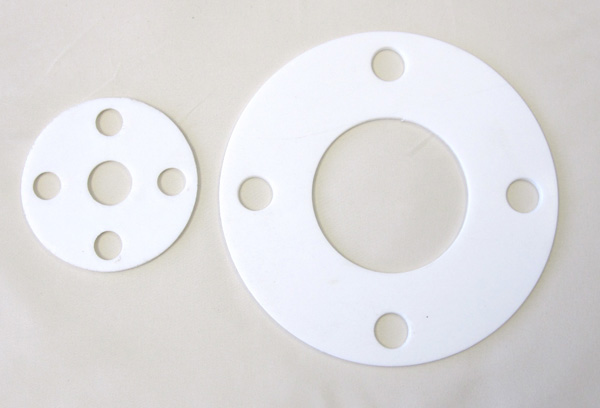

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services