Open cell foam is foam material in which the cells or bubbles of the polymer are interconnected and do not maintain sealed and separate compartments. Compared to closed cell foam, the other main type of foam, open cell foam is more permeable to moisture vapor and provides less resistance to pressure, allowing it to be used when softness and conformability are required. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Open Cell Foam Companies

Different types of open cell foam include open cell polyurethane, open cell polyester, open cell polyamide. Air typically fills the spaces within the open cells, making open cell foam an excellent thermal insulation provider. The insulation value is related to the specifications of the cell alignment within the foam.

Foam materials are synthetically produced and as such can vary widely in terms of density, porosity, size and thickness. Open cell foam is widely used in construction and residential applications to provide thermal barriers to improve the quality of air within a space.

Using insulation foam also lowers energy costs and HVAC requirements, and can additionally provide air filtration from unwanted particles. Other common uses of open cell foam materials include in automotive and furniture seating as foam cushioning, as foam padding for mattresses, recreational equipment and appliances, as packaging material, sponges and scrubbers and medical foam.

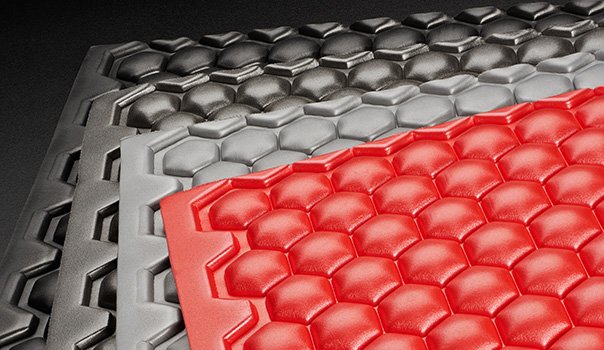

As foam is a widely versatile material and can be fabricated to suit any number of applications, there are important specifications to consider when determining the best type and size to use. Density, tensile strength, temperature, thermal conductivity, abrasiveness and compressibility are factors which vary with type of foam and can directly affect the results of the material's use.

Foam also tends to break down over time, especially if it is exposed to frequent wear and tear. Therefore it will need to be replaced at some stage in almost every application. Open cell foam is a less dense material than closed cell foam and so tends to be a more cost-effective solution for many foam applications. However, due to its tendency to soak up and retain water, open cell foam cannot be used for many of the floatation and buoyancy uses for which closed cell foam is so popular.

Reticulated foam, which is open cell foam with very interconnected cells and high porosity levels, is an ideal material for applications in which retention and large surface areas are desired such as filtering materials, fuel tank inserts and loudspeaker covers. Open cell foam is able to trap particles and unwanted elements while allowing the passage of air and/or liquids.

Die Cutting

Die Cutting Foam Fab

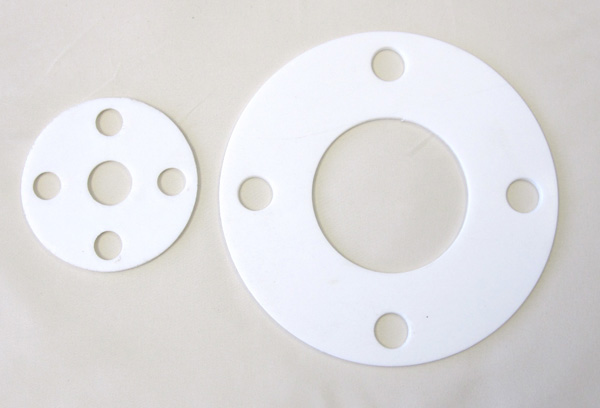

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services