Flextech

FlextechRequest A Quote

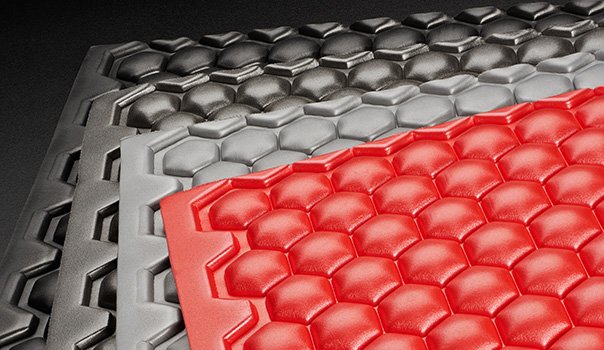

St. Louis Park, MN | 952-345-0012For more than 25 years, FLEXTECH has been delivering custom, engineered foam solutions to a number of markets including medical, industrial and military/tactical. Our expertise is in foam laminating and thermoforming. Our thermoforming capabilities include compression molding, vacuum forming and encapsulation molding. These capabilities allow us to provide foam components with unique properties and functionality. The FLEXTECH team is comprised of members who are all committed to providing an exceptional level of service and responsiveness throughout our customers’ experience. We have a core group of personnel that includes technical sales professionals and engineers, most of whom have been in the foam fabrication industry for their entire careers. Our depth of experience allows us to draw from thousands of different foam fabrication projects over the years and in turn provide innovative solutions for our customers’ most challenging projects. Our success is based largely on our ability to collaborate with you on the design and development of innovative foam solutions for your new applications. Our sales and product development team members have extensive experience working closely with our customers throughout the design and development process. Ideally, we are involved at the conceptual phase and can educate our customer on materials and their properties, our production capabilities and process limitations, etc. FLEXTECH has built a very loyal customer base by delivering innovative foam solutions and consistently providing an exceptional level of customer service. From your initial contact with a Flextech sales person, through the development process with our engineers and on to our customer service associates, we endeavor to be the most responsive, customer oriented foam fabricator in the industry. We invite you to connect and collaborate with our sales and engineering team and bring your new product to fruition. Let us show you the Flextech advantage!

Die Cutting

Die Cutting Foam Fab

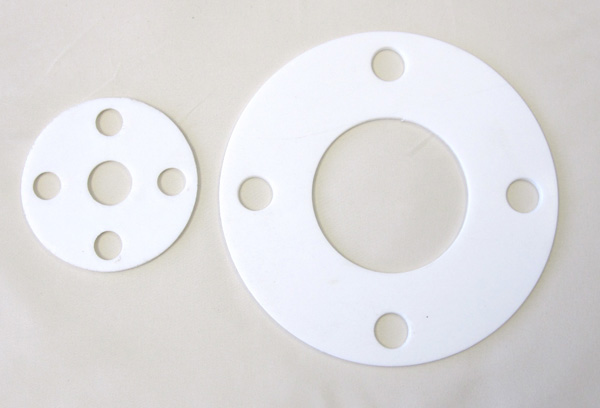

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services