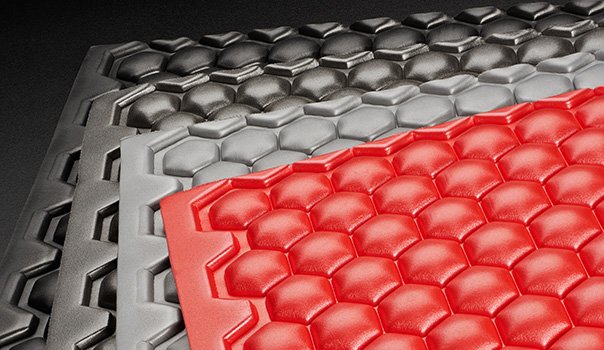

Laminating foam is useful to customers in industries including: aerospace, appliance, automotive, construction, consumer product, electronics, healthcare, HVAC, flooring, marine, military and sports and recreation. They use laminated foam in a number of different applications, such as: sound barrier, heat resistance and liquid and gas containment. They can also be used as: foam surfaces, wheelchair cushions, stretcher pads, positioners, professional displays, interior fender panels, truck liners, footwear and even garments. Read More...

Flextech has a range of lamination capabilities that allow us to manufacture custom composites from a variety of foams and other substrates. The substrates include, but are not limited to, open and closed-cell foams, knit and woven textiles, thermoplastic films, pressure-sensitive adhesives and other specialized materials. We will work with you to thoroughly understand your application to...

More Laminating Foam Companies

Laminated foam composites – Flextech, Inc.

There are a number of different foam laminating methods available to fabricators, the most common of which are adhesive lamination and and flame lamination. During adhesive lamination, fabricators laminate the foam using bonding agents, such as pressure sensitive adhesive (PSA). Agents may be applied directly onto both surfaces, or they may be applied indirectly as pre-coated release liners called transfer transfer tape. During flame foam lamination, fabricators pass the foam over an open flame, which creates a thin layer of molten polymer on its surface. Then, fabricators bring this surface in contact with the substrate while applying pressure. This creates a bond the foam and the substrate.

Other methods include heat preparation, which is common for sealing bags, and corona treating. Machines fabricators may use to achieve the perfect laminated part include: flame laminators, cold laminators, hand fed laminators, automatic laminators, pouch laminators or roll laminating machinery.

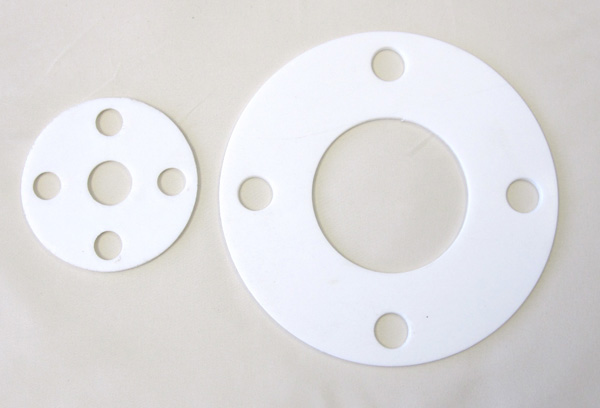

Laminating foam fabricators can customize your foam products in a number of ways. For example, if you’re ordering laminated white foamboard, fabricators can typically offer it to you in different finishes, like: matte, sticky and gloss. They can also add custom prints. Not sure if laminating foam is right for you, or have questions about your potential foam application? To learn more about the possibilities with laminating foam, contact one of them many excellent companies we have listed on this page.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services