Foam padding is low-density flexible foam used in a wide range of applications such as upholstery, bedding, packaging, protective sports wear and more. Typical materials used in the fabrication of different types of foam include polyester, polyether, polystyrene, polyurethane, polyethylene and vinyl. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Padding Companies

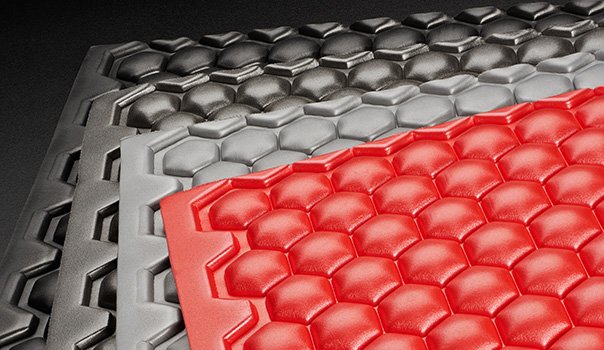

Foam is described as open cell foam or closed cell foam depending on the arrangement of the material cells. Closed cell foam is made up of sealed and unbroken cells or bubbles that are in a tight configuration resulting in dense foam that provides a strong surface.

Open cell foam is more flexible as the cells of the material are broken, or open. It is softer and less dense and is commonly used to make padding for a number of furniture applications such as barstools, carpets, benches and camping pads. Specific types of foam are chosen according to their different properties and according to the requirements of the application.

polyurethane foam is also referred to as PE, and is rigid foam constructed through an extrusion process. Beds, couches, chairs and other furniture all use PE as primary structural padding. Polyethylene foam on the other hand is used widely in packing cases to provide support and protection for fragile goods. It is extremely lightweight and durable, and has excellent buoyancy. It is also used in a number of flotation devices and nautical equipment.

Padding made from foam is lightweight, shatter proof and wear and tear resistant. It is easy to fabricate into the required shapes and dimensions for an application, and offers a cost-effective padding solution. It can also be used for insulation and to minimize effects of vibrations, in seals and gaskets, as elastomeric wheels and tires, for rotational transfer molding cores and expansion joint filler in masonry and concrete applications.

Another advantage to using foam padding, especially closed cell foam padding, is that it is impervious to mold, moisture and bacterial growth and is able to be used in outdoor applications for a long time without breaking down or becoming unsanitary.

The resistance of foam to absorbing water is a property which ensures its usefulness in applications such as medical foam or filter foam. Unlike other materials which may trap bacteria and water, closed cell foam resists it, thus preventing moisture build up and bacterial growth over time. Foam materials are easy to fabricate and can come in almost any size, thickness and shape. They can also be fabricated in a wide variety of colors.

Die Cutting

Die Cutting Foam Fab

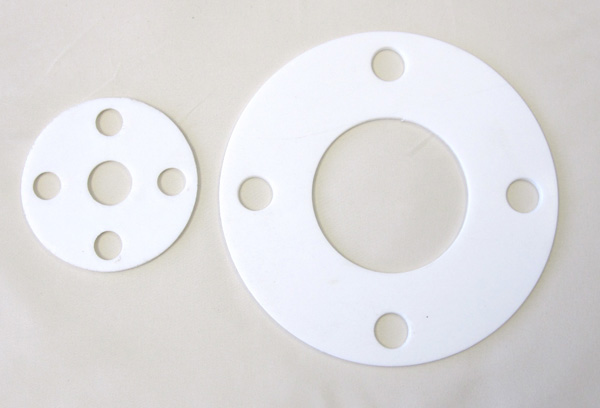

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services