Wm. T. Burnett & Co.

Wm. T. Burnett & Co.Request A Quote

Baltimore, MD | 800-638-0606https://www.williamtburnett.com//

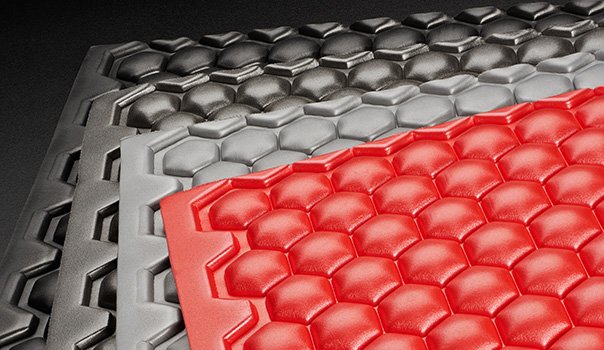

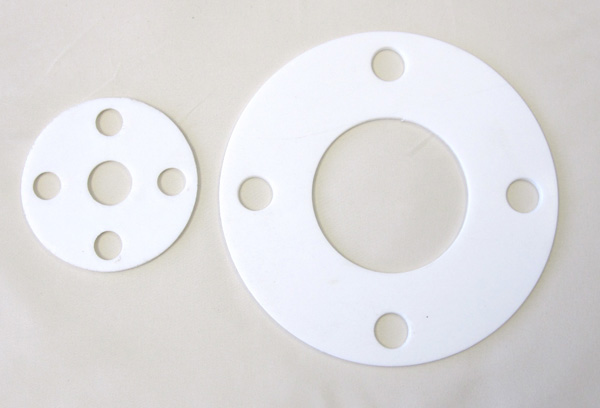

Wm. T. Burnett & Co., headquartered in Baltimore, MD, is a leading provider of foam fabricating solutions with a rich history dating back to 1898. With over a century of experience in the industry, Wm. T. Burnett & Co. has established itself as a trusted name in foam fabrication, known for its commitment to quality, innovation, and customer satisfaction. Wm. T. Burnett & Co. offers a comprehensive range of foam fabricating products and services to meet the diverse needs of its clients. Specializing in foam conversion, they work with a variety of foam products and materials. They offer double cell sponges, reticulated foams, flame retardant foams, felted foams, hydrophilic & hydrophobic foams, low permeability foams, anti-static foams, anti-microbial foams, and more.. Their extensive selection of foam materials allows them to provide tailored solutions for various industries and applications. The company's foam fabricating capabilities are driven by state-of-the-art equipment and technologies. With advanced cutting, shaping, and contouring capabilities, including CNC routing, die cutting, and waterjet cutting, they can produce foam products with precision and efficiency. Whether it's foam sheets, rolls, pads, or custom components, Wm. T. Burnett & Co. has the expertise and resources to meet the unique requirements of each project. Quality is of utmost importance to Wm. T. Burnett & Co. They adhere to rigorous quality control processes throughout the foam fabrication process to ensure that every product meets or exceeds customer expectations. From material selection and testing to final product inspection, their dedicated quality assurance team ensures that the foam products meet the highest standards of performance, durability, and reliability. Wm. T. Burnett & Co. serves a wide range of industries, including automotive, packaging, construction, aerospace, and more. Their foam fabricating products find applications in cushioning, insulation, soundproofing, gasketing, and protective packaging. Whether it's designing foam inserts for fragile products, creating custom foam packaging solutions, or developing specialized foam components, they have the expertise to deliver solutions that cater to the unique needs of each industry. For companies in need of foam fabrication services, Wm. T. Burnett & Co. offers the expertise, resources, and customer-centric approach necessary to deliver foam products that meet the highest standards of quality, performance, and reliability.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services