JBC Technologies, Inc.

JBC Technologies, Inc.Request A Quote

North Ridgeville, OHJBC Technologies, Inc., located in North Ridgeville, OH, is a leading provider of foam fabricating solutions with a strong focus on delivering innovative products and exceptional service. With a rich history spanning over three decades, they have established themselves as a trusted partner for businesses in need of customized foam solutions for various applications.

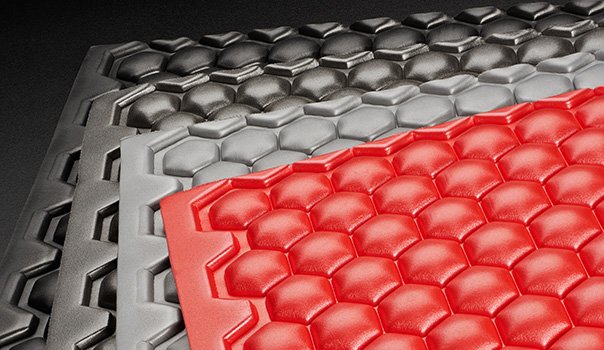

At JBC Technologies, foam fabricating is their expertise. Their products include noise abatement products, thermal insulation products, custom foam options, flexible graphite, foams, spine rubbers, felt, fabric, and flocking. Their highly skilled team of engineers and technicians leverage their expertise and industry knowledge to transform foam materials into high-quality, precision-cut components that meet the specific needs of their customers.

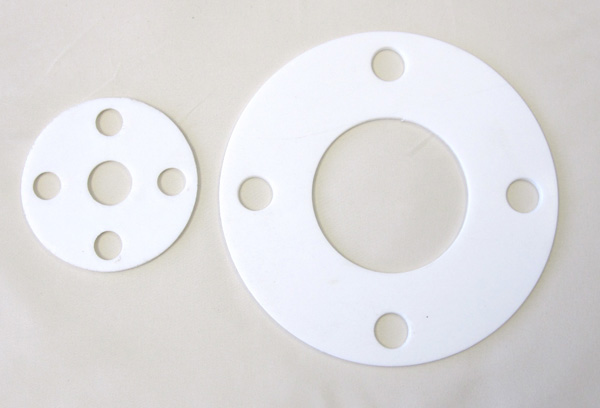

One of their core offerings is foam gaskets and seals. JBC Technologies understands the critical role that gaskets and seals play in ensuring airtight and watertight seals, preventing leakage, and providing protection against environmental factors. They have the capabilities to design and manufacture custom foam gaskets and seals that are tailored to each customer's unique requirements, providing reliable performance and excellent sealing properties.

JBC Technologies also specializes in foam insulation solutions. They offer a range of foam insulation products that provide thermal insulation, soundproofing, and vibration-damping properties. Whether it's for HVAC systems, automotive applications, or industrial equipment, their foam insulation solutions help enhance energy efficiency and reduce noise and vibration levels.

In addition to gaskets, seals, and insulation, JBC Technologies offers foam components for various industries and applications. Their foam fabricating capabilities extend to creating foam pads, cushions, dampers, and custom foam parts for automotive, electronics, medical, and consumer product applications. With their advanced cutting and shaping technologies, they can produce intricate foam components with high precision and consistency.

JBC Technologies takes a customer-centric approach to their services. They work closely with clients to understand their specific requirements and challenges, collaborating to develop custom foam solutions that meet their needs. Their capabilities include rotary die-cutting, dieless cutting, laminating, embossing, perforating, slitting surface treatment, clean room manufacturing capabilities, precision die cutting, materials converting, and rapid prototyping. They also help with supply chain consulting, value analysis, and engineering services.

With their extensive industry knowledge, dedication to quality, and customer-focused approach, JBC Technologies is a trusted partner for businesses seeking foam fabricating solutions. Their ability to deliver customized foam components, combined with their commitment to innovation and customer satisfaction, sets them apart in the industry.

Whether it's foam gaskets, seals, insulation, or custom foam components, JBC Technologies has the expertise and capabilities to provide innovative and reliable solutions. They continue to be a go-to provider of foam fabricating solutions, helping businesses across various industries achieve optimal performance and functionality with their foam-based products.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services