Hotwire Direct

Hotwire DirectRequest A Quote

Clarkston, WA | (800) 555-4042Hotwire Direct, located in Clarkston, Washington, is a leading foam fabricating solution provider specializing in hot wire cutting technology. With a strong commitment to quality, creativity, and customer satisfaction, Hotwire Direct has established itself as a trusted partner for foam fabricating projects across various industries. At the core of Hotwire Direct's offerings is their expertise in hot wire foam cutting. They employ state-of-the-art equipment and advanced computer-controlled systems to precisely cut foam materials into intricate shapes, contours, and designs. They offer a variety of foam-cutting equipment, including CNC machines, portable miters, hotwire shapers, hot knives, glue guns, and other foam fabrication options. This technology allows them to create custom foam products that meet the unique requirements of each project, whether it's architectural elements, signage, props, packaging, or other foam-based applications. With their hot wire cutting capabilities, Hotwire Direct can easily produce complex and precise foam shapes. Their skilled technicians and designers work closely with clients to understand their needs and translate their ideas into reality. From simple geometric shapes to intricate 3D models, Hotwire Direct has the expertise to deliver foam products that meet the highest standards of craftsmanship and design. One of the key advantages of Hotwire Direct's foam fabricating process is its efficiency and cost-effectiveness. The hot wire-cutting technology enables them to produce foam components with minimal material waste, resulting in optimized production timelines and reduced costs. Additionally, the precise nature of hot wire cutting ensures consistent quality and accuracy in every foam piece, eliminating the need for extensive post-production modifications. Hotwire Direct is committed to providing exceptional service to its customers. Their team works closely with clients throughout the project, from initial concept development to final production. They offer valuable guidance and recommendations, leveraging their expertise to ensure the foam fabricating solutions meet the client's requirements and expectations. Hotwire Direct also provides quick turnaround times to meet tight deadlines without compromising on quality. In addition to its foam fabricating capabilities, Hotwire Direct offers comprehensive support services to assist clients in achieving their desired outcomes. They provide assistance with design, engineering, and prototyping, utilizing advanced software tools and CAD/CAM systems to create precise foam templates and cutting paths. Their knowledgeable team can also offer advice on material selection, finish options, and assembly techniques to optimize the performance and aesthetics of the foam products. Hotwire Direct's commitment to innovation and customer satisfaction sets them apart in the foam fabricating industry. They continuously invest in research and development to explore new techniques, materials, and applications, ensuring they stay at the forefront of foam-cutting technology. Their dedication to excellence has earned them a solid reputation as a trusted provider of high-quality foam fabricating solutions. Whether creating eye-catching architectural elements, intricate packaging designs, or custom foam props, Hotwire Direct has the expertise, technology, and creativity to deliver exceptional foam fabricating solutions. They pride themselves on their ability to turn concepts into reality, providing clients with foam products that are visually stunning, precise, and functional. Hotwire Direct is a leading provider of foam fabricating solutions, leveraging its expertise in hot wire cutting technology to create custom foam products for various industries. With their commitment to quality, innovation, and customer satisfaction, Hotwire Direct is the ideal partner for companies seeking creative and reliable foam fabricating services in Clarkston, Washington, and beyond.

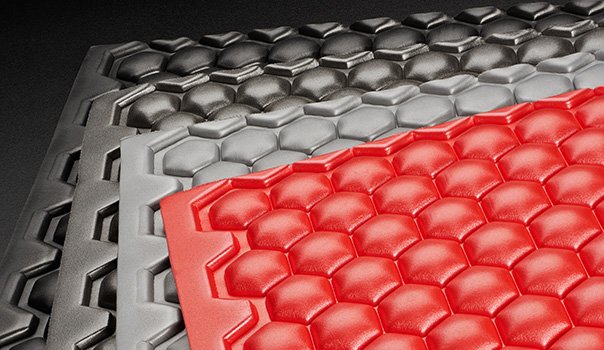

Die Cutting

Die Cutting Foam Fab

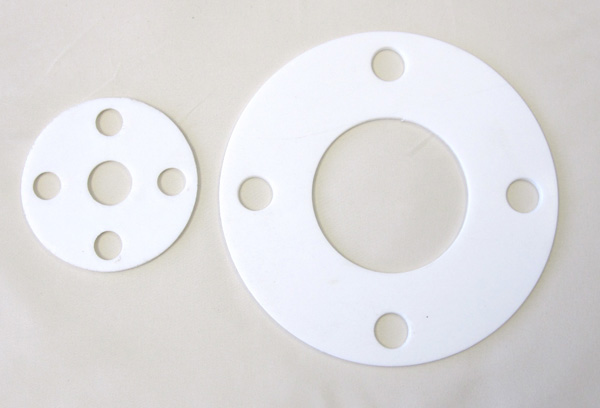

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services