Flexible polyurethane foam (FPF) is a polymer made from a chemical process that combines polyols and isocyanates. FPF is distinguished by a cellular structure that allows for some compression and resilience, resulting in a cushioning effect. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

At Melmat, Inc., we specialize in custom foam fabricating solutions designed to meet the diverse needs of industries requiring reliable protective packaging, cushioning, and insulation. With decades of experience, we take pride in engineering foam products that balance precision, durability, and performance.

More Flexible Foam Companies

What is Flexible Foam?

Flexible foam is a versatile, lightweight material engineered from a range of polymers, most notably polyurethane. It is a core component in countless everyday products and industrial applications due to its unique combination of resilience, comfort, and customizability. Flexible foam is often produced in large slabs, known as slabstock buns, which are allowed to cure into a solid yet pliable substance. After curing, these buns are sliced and molded into smaller pieces, tailored to fit a wide variety of shapes, sizes, and designs depending on the intended use.

The manufacturing process begins when liquid chemicals—primarily polyols and isocyanates—are dispensed onto a conveyor belt. These chemicals immediately react, producing a foaming action that causes the material to expand and rise into a substantial "bun," typically about four feet high, as it moves along the conveyor. Once set, the foam exhibits its characteristic flexibility and cushioning properties, making it an ideal choice for both consumer and industrial markets.

How Flexible Polyurethane Foam is Made

The production of flexible polyurethane foam (FPF) involves a carefully controlled chemical reaction between polyols and isocyanates, often aided by water, surfactants, catalysts, and various additives. While slabstock production is the most common method, foaming materials can also be poured into aluminum or custom molds. In these cases, the cured foam adopts the precise dimensions and contours of the mold, enabling the creation of complex foam products that would be impossible to form using conventional slabstock techniques.

Foam molding is particularly valuable for high-volume manufacturing operations where consistent shape and quality are essential. Automotive seating is a classic example: car seat headrests and cushions are often molded directly over metal frames to ensure a precise fit and optimal comfort. Due to the expense and time required to produce custom molds, this method is best suited for large production runs in industries such as automotive, furniture, and aerospace.

Molded foam is widely used in the production of automotive interiors, ergonomic office furniture, medical devices, and sporting goods. To achieve specific performance characteristics, manufacturers supplement FPF's base materials with specialized additives. These may include flame retardants for enhanced fire safety (crucial for transportation and public spaces), antimicrobials for outdoor and marine applications, and impact modifiers for improved shock absorption. This customization ensures that flexible foam products meet stringent regulatory and end-user requirements.

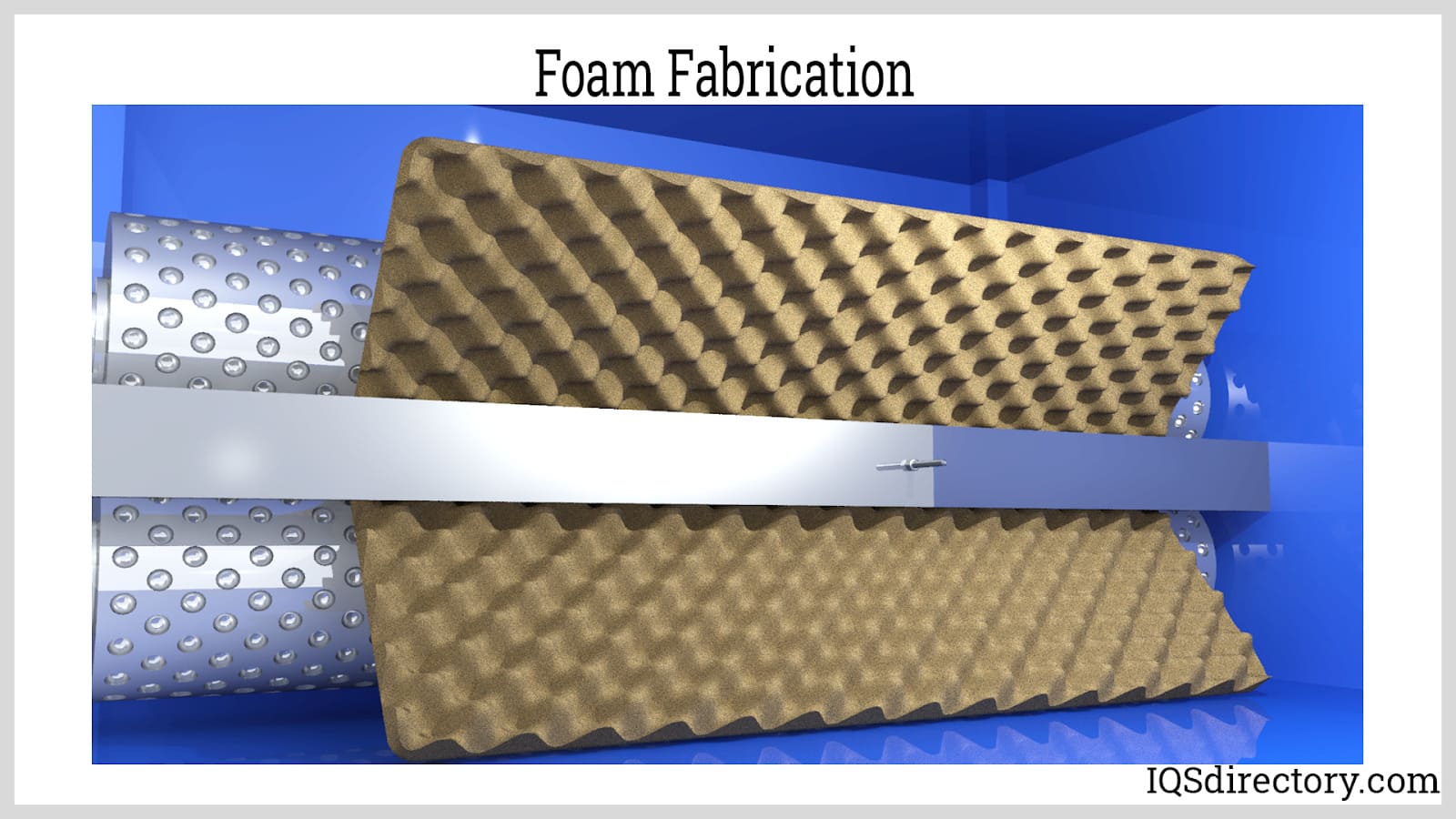

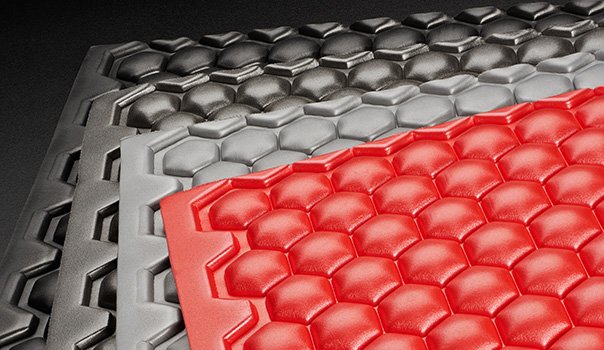

The versatility of flexible foam extends beyond chemistry. Once the foam is produced, it can be fabricated or converted into intricate shapes using advanced machinery. Vertical bandsaws, horizontal slitters, and die-cutting presses are traditional tools, while modern operations may use lasers, hot wires, computer-controlled water jets, and convoluting machines. For example, foam can be compressed and sliced to create "egg crate" or "convoluted" surfaces, commonly found in mattress toppers and acoustic panels for sound dampening.

Flexible foam’s inherent pliability allows it to be shaped with exceptional precision. Techniques such as loop slitting, where foam is mounted on a vertical wheel with cutting blades, enable the production of continuous rolls or sheets. Advanced technologies, including CNC-controlled cutting and digital patterning, support the fabrication of custom foam inserts for packaging, medical equipment, and consumer products.

Properties of Flexible Foam

Understanding the key physical and mechanical properties of flexible foam is crucial for selecting the right material for a specific application. These properties are closely tied to the foam’s composition, cell structure, and manufacturing method.

- Bulk Density: The bulk density of polyurethane foam is not solely determined by its chemical composition but by the ratio of its mass to its overall volume. Density is a primary indicator of a foam’s load-bearing capacity, durability, and price. Higher-density foams generally offer superior resilience, longevity, and support, making them well-suited for high-performance seating, bedding, and packaging applications. Density is typically measured across multiple layers of a sample block, perpendicular to the foam’s growth axis, to ensure consistent performance.

- Load-Bearing Capacity: This property describes how much compressive force the foam can withstand without sustaining permanent deformation. It reflects the material’s firmness or stiffness, which is critical for applications such as mattresses, cushions, and ergonomic supports. Two common industry-standard tests—Indentation Force Deflection (IFD) and Compression Load Deflection (CLD)—are used to quantify load-bearing capacity.

- Cell Structure: Flexible foam consists of a network of interconnected cells. The size, shape, and openness of these cells influence properties such as breathability, moisture resistance, sound absorption, and resilience. Open-cell foams are soft, compressible, and provide excellent cushioning and sound dampening, while closed-cell foams are more rigid, water-resistant, and insulative.

- Thermal Insulation: Due to its structure, flexible polyurethane foam offers good thermal insulation properties, making it suitable for temperature-sensitive packaging, HVAC insulation, and cold chain logistics.

- Flame Retardancy and Chemical Resistance: By incorporating specific additives, flexible foams can be engineered for enhanced fire resistance, chemical inertness, and microbial protection, meeting regulatory requirements for public transportation, healthcare, and hospitality industries.

Common Questions About Flexible Foam Properties

- How do I choose the right foam density for my application? Consider the required support, expected weight load, and desired durability. Higher-density foams are ideal for frequent-use products, such as mattresses and commercial furniture.

- What affects the comfort and resilience of a foam product? Factors include cell structure (open or closed), chemical additives, and manufacturing process. Open-cell foams provide superior comfort and airflow, while closed-cell foams enhance durability and moisture resistance.

- Are there flexible foams suitable for outdoor or specialized environments? Yes, specialty additives can make foams UV-resistant, antimicrobial, or flame-retardant for demanding environments like marine, healthcare, or transportation.

Applications of Flexible Polyurethane Foam

Flexible polyurethane foam is renowned for its adaptability and is used in a vast array of industries. Its unique properties—such as compressibility, resilience, and customizable firmness—make it indispensable in both consumer and commercial markets. Here are some of the primary and emerging use cases:

- Furniture and Bedding: Flexible foam is a key material in sofas, chairs, mattresses, mattress toppers, pillows, and ergonomic supports. It provides comfort, support, and shape retention, often meeting strict fire safety and durability standards.

- Automotive Interiors: Used in car seats, armrests, headliners, door panels, and noise-dampening components, flexible foam enhances passenger comfort, safety, and acoustics.

- Packaging and Protective Inserts: Its shock-absorbing properties make flexible foam ideal for custom packaging, protecting fragile items during shipping and handling. Foam inserts are common in electronics, medical device, and industrial equipment packaging.

- Medical and Healthcare: Flexible foam is used in wheelchair cushions, orthopedic supports, patient positioning devices, surgical pads, and wound care products due to its pressure-relieving and hypoallergenic properties.

- Acoustic and Soundproofing: Open-cell flexible foam is effective at absorbing sound waves, making it widely used in recording studios, offices, and industrial environments for noise reduction and vibration dampening.

- Filtration and Fluid Management: Reticulated flexible foam features a highly open cell structure, making it suitable for air and liquid filtration in appliances, HVAC systems, and automotive fuel tanks.

- Sports and Leisure: Helmets, protective padding, yoga mats, and athletic shoes often contain flexible foam for impact absorption and comfort.

- Construction and Insulation: Flexible foam is used as a sealant, gap filler, and insulator in building and construction, providing energy efficiency and sound insulation.

Polyurethane foam can be laminated with other materials—such as nonwoven substrates, textiles, fibers, and netting—using bonding techniques like flame bonding, hot film adhesion, hot melt lamination, and powder lamination. These processes enhance the foam’s durability, aesthetic appeal, and functionality, broadening its application scope in apparel, footwear, and technical textiles.

Reticulation, a process that increases the porosity and airflow of foam, is achieved by breaking down cell walls through controlled chemical or physical means. Reticulated foam is critical for applications requiring high breathability and filtration, such as air and water filters, speaker grills, and anti-surge membranes in fuel tanks. Its open cell structure also enables rapid drying, making it suitable for marine and outdoor applications.

Sustainability is an evolving focus in the foam industry. The recycling and repurposing of foam scrap into bonded carpet cushion is one of the most significant forms of commercial foam recycling. Scrap foam is shredded, mixed with chemical adhesives, compressed, and steam-injected to produce large foam blocks. These are then sliced into carpet underlays. With a market share exceeding 80%, bonded foam is the leading material for carpet cushions, contributing to waste reduction and circular economy goals.

Benefits of Flexible Foam in Product Design and Manufacturing

- Customizable Comfort: Tailor foam density, firmness, and shape to match ergonomic, aesthetic, and functional requirements.

- Lightweight and Durable: Reduce product weight without sacrificing support or resilience.

- Cost-Efficient: Scalable production and material efficiency lower total system costs for manufacturers and end-users.

- Thermal and Acoustic Performance: Flexible foam improves energy efficiency and soundproofing in residential, commercial, and industrial settings.

- Safe and Compliant: Formulations can meet stringent health, safety, and environmental standards, including fire retardancy and low VOC emissions.

- Design Flexibility: Easily fabricated, cut, and shaped to fit custom applications, from medical devices to electronics packaging.

Looking for the Best Flexible Foam for Your Project?

Not sure which type of flexible foam is right for your needs? Explore our in-depth guides on polyurethane foam, molded foam, and other specialty foams. Consider the following prompts as you research:

- What are the primary performance requirements for your application (load-bearing, comfort, insulation, sound absorption)?

- Will the foam be exposed to moisture, chemicals, UV light, or extreme temperatures?

- Do you need custom shapes or sizes, or will standard sheets and rolls suffice?

- Are sustainability and recyclability important in your project or supply chain?

- What industry certifications or compliance requirements must your foam products meet?

Choosing the Right Flexible Foam Manufacturer

Selecting the ideal flexible foam manufacturer is a critical step in ensuring product quality, performance, and longevity. When sourcing foam, consider supplier expertise, manufacturing capabilities, and industry certifications. Here’s how you can make an informed purchasing decision:

- Evaluate Technical Expertise: Look for manufacturers with extensive experience in producing custom and standard flexible foam products. Review their track record in your industry, whether it’s automotive, healthcare, packaging, or consumer goods.

- Assess Manufacturing Capabilities: Can the supplier provide both high-volume and small-batch production? Do they offer in-house design, prototyping, converting, and testing services? Advanced fabrication capabilities—including CNC cutting, die-cutting, lamination, and custom molding—can add value and reduce lead times.

- Review Quality and Compliance: Ensure the manufacturer adheres to industry standards such as ISO 9001, CertiPUR-US, UL, or other relevant certifications. Compliance with fire safety, environmental, and health regulations is essential for many applications.

- Consider Sustainability Initiatives: Ask about the supplier’s foam recycling programs, use of bio-based or low-VOC materials, and environmental stewardship.

- Request Samples and Prototypes: Working with manufacturers who provide samples and prototyping can help you validate material performance before committing to large production runs.

- Compare Pricing and Lead Times: Use our RFQ (Request for Quote) system to obtain competitive pricing and delivery schedules from multiple flexible foam suppliers.

To ensure the most constructive outcome when purchasing flexible foam from a flexible foam manufacturer, it is important to compare several companies using our directory of flexible foam manufacturers. Each flexible foam manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Ready to Get Started?

Take the next step:

- Compare flexible foam manufacturers in our comprehensive directory.

- Contact suppliers directly for technical support, custom quotes, and sample requests.

- Explore our resources to learn more about foam types, fabrication methods, and application-specific solutions.

Frequently Asked Questions About Flexible Foam

- What’s the difference between open-cell and closed-cell flexible foam? Open-cell foam is softer, more breathable, and better for sound absorption, while closed-cell foam is firmer, more resistant to moisture, and insulates better.

- How do I specify flame retardant or antimicrobial foam? Consult with your supplier about required additives and certifications for your industry or application.

- Can flexible foam be recycled or repurposed? Yes, many manufacturers offer recycling programs and foam scrap can be processed into bonded carpet cushion and other secondary products.

- What are typical lead times for custom foam fabrication? Lead times vary by order complexity and volume, but most suppliers offer prototyping and expedited services for urgent projects.

For more information, technical guidance, or to request a custom quote, browse our supplier directory or contact us today.

Die Cutting

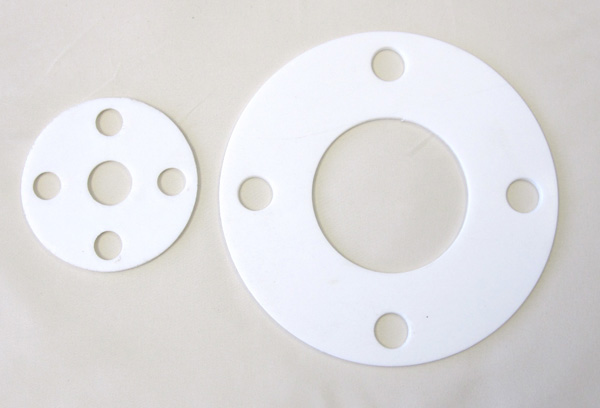

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services